Regular preventive saw blades maintenance will increase productivity by reducing costs, downtime and stress during the use of the saw blade.

Preventive maintenance will help extend the life of the saw blade while reducing the need for emergency repairs and improving the safety of mechanical work.

Al mismo tiempo, a well-maintained bandsaw can complete efficient and high-quality cuts.

Knowing the preventive maintenance procedures for saw blade is of great significance to all bandsaw machine owners. So what does the specific maintenance procedure include? When will the maintenance measures be carried out? En este articulo, we will briefly talk about it. I hope that after reading this article, you will have a better understanding of saw blade maintenance.

About the maintenance of the saw blade itself

-Before starting the machine, the saw blade tension is one of the most important maintenance items. It needs to be adjusted to the most appropriate blade tension according to different machine types, cutting materials, cutting speeds and other factors to avoid problems with the blade due to excessive or insufficient tension;

-When you need to remove the saw blade, you need to monitor the blade trajectory before performing the removal action. Note that the correct spacing between the blade rear edge and the wheel rim should be approximately one-eighth of an inch;

-After each saw blade change, check the pulley and check the tension of the newly installed blade according to the band saw machine manufacturer’s recommendations.

About the Maintenance of Other Saw Blade machine parts

-Transmission oil level: Check the transmission for defective bearings or seals;

-Drive wheel: Is there excessive play in the drive wheel;

-Pulley: Is the pulley properly aligned, properly tensioned, and is the pulley itself worn? If worn, be sure to replace it with a new one immediately;

-Belt: Is it worn, cracked, and can it stretch normally;

-Vise: Can the vise be fixed or moved normally, and align the vise and blade;

-Also note that the installation of the guide rail must comply with the machine manufacturer’s instructions;

Daily Maintenance Tasks

-Check the guide rail alignment daily;

-Check the chip removal system daily to ensure that the conveyor system is working properly and all chips are removed;

-Monitor the saw fluid daily, keep the fluid level within specifications, and ensure that the fluid in all nozzles flows freely;

-Check the hydraulic system daily and check the oil level frequently.

Other Maintenance Considerations

– Check the belt speed weekly and monitor the maximum or minimum speed of the belt. If an abnormal speed occurs, stop the machine and check it in time;

– Monitor the pulley bearings every six months to check for abnormal wheel movement and replace the pulley bearings if necessary;

– Check the belt guide at least every six months;

– The drive must be checked every six months, visually inspect all bearings to ensure that there are no obvious abnormalities in the bearings;

Preventive maintenance will improve cutting performance and achieve the best life expectancy by reducing the need to replace dull and fragile blades. A well-maintained bandsaw machine performs better, and taking the time to perform maintenance regularly will ensure optimal performance.

Comprehensive working knowledge and maintenance procedures are essential for any successful manufacturing work. Equally important, the bottom line of any bandsaw operator is safety to ensure a smooth and efficient cutting process.

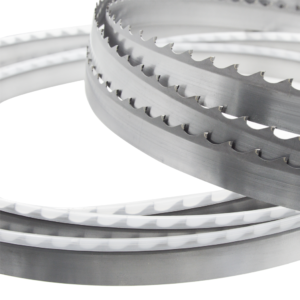

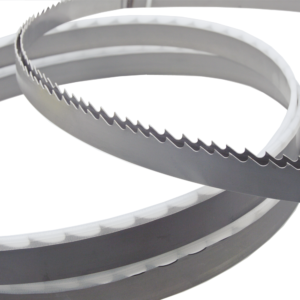

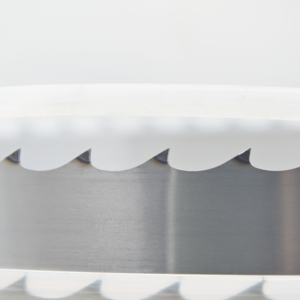

Wood Log Sawing Sawmill Timber TCT Bandsaw Pine Woodworking Carbide Tipped Band Saw Blade for Sawing