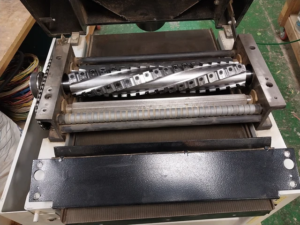

The replacement and installation of the helical spiral cutter head is closely related to the use effect of the cutter. In addition to installing it according to the instructions of the machine supplier, there may be some small details that carpenters have not noticed.

These details may affect whether the spiral cutter head can be used smoothly. If you are also interested in this, why not discuss the relevant installation methods and precautions with me!

Let’s first discuss what to pay attention to if the ordinary cutter head is replaced with a spiral cutter head:

· Check the accuracy of the original bearing; if a higher precision bearing is required, it is recommended to replace the new bearing, and the replacement bearing should use a P5 grade low-noise high-precision bearing.

· Check the inner diameter of the bearing seat on the planer; due to the long-term use and wear of the inner hole of the bearing, the noise is high, which will cause the bearing to be damaged in a short time, causing the bearing to go inside or outside the circle. If there is a problem with the bearing seat, a new bearing seat must be replaced.

Next is the precautions for the installation of the spiral cutter head:

1-Before installing the bearing, check and clean the shaft head and shaft seat; when installing the bearing, the bearing should be pressed in smoothly and evenly.

If there is hydraulic equipment, please use it to install the bearing. If there is no hydraulic equipment, use a steel sleeve to evenly contact the inner ring of the bearing to avoid damaging the outer circle of the shaft head.

Use an air gun or brush to remove debris, dust and other foreign matter on the knife shaft. Ob istem času, you also need to remove debris and dust on the cutter seat to ensure that the cutter seat is clean. To clean the knife seat and blade, it is recommended to use gasoline or thinner for easy cleaning.

2-When the spiral cutter head has been installed on the machine, when replacing the blade, the power of the equipment must be turned off first.

The blade has four blade surfaces. If one of the blades is blunt, tighten the screw counterclockwise; when replacing the blade surface, be sure to pay attention: each blade surface has a marking point, and it must be uniformly oriented to avoid the new and old blades being installed on the wrong surface, resulting in an uneven planing surface.

3-If the screw is too tight or rusty and difficult to loosen, first put the drill bit into the screw plum hole, tap it gently with a small hammer (be careful not to damage the blade), and then use a wrench to easily loosen it.

In order to avoid the phenomenon that the screws are rusted and difficult to loosen when changing the blade next time, it is recommended to clean the screw holes first every time you change the blade, and then apply engine oil to the screws and screw them into the screw holes, so that the screws can be easily loosened when changing the blade next time.

4- Gently press down the woodworking cutter head, slide a few times, make the bottom of the blade fit with the cutter seat, lock the screws clockwise, and the blade will automatically press on the positioning table of the cutter seat.

Opomba: To ensure that the screws and screw holes will not bite, rust firmly, and avoid easy loosening next time, the screws need to be lubricated with oil when changing the blade.

5- Carefully check whether the woodworking cutter head is placed correctly on the knife seat to avoid blade breakage or blade cutting surface caused by locking the blade.

Please check the woodworking cutter head before use. If there are cracks, please replace it immediately to avoid safety accidents and product damage. Check the screws frequently to avoid loose screws.

The above are the details that we have summarized that woodworking friends may need to pay attention to when replacing and installing a new cutter head. See if there are any small details that you will overlook.

If you have any questions when using woodworking tools, or you are looking for a supplier of woodworking tools, you can always contact us. DH is a woodworking tool manufacturer from China with more than 25 years of manufacturing experience, rich product lines and extremely high product quality.