Solid carbide spiral router bits (also called milling cutters) are mainly used for milling and milling on CNC milling machines. Spiral router bits are usually made of 100% pure tungsten carbide to ensure the quality and performance of solid carbide spiral milling cutters.

How much do you know about spiral router bits? Read on to see if there are any points about carbide spiral milling cutters that you don’t know.

TYPES OF SPIRAL ROUTER BITS

According to the number of cutting edges, spiral milling cutters can be divided into single-flute, double-flute, three-flute and compound milling cutters; In wéet k'iin, on the basis of the number of flutes, they are also divided into up-cut and down-cut; that is, single-flute spiral milling cutters include up-cut single-flute milling cutter, down-cut single-flute milling cutter, and double-flute spiral milling cutters are also divided into up-cut double-flute and down-cut double-fulte.

SINGLE-FLUTE DOUBLE-FLUTE THREE-FLUTE

CUTTING TYPES

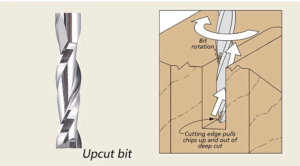

·Up-cut Milling Cutter

Up-cut cutting, the groove direction of the milling cutter is upward from left to right.

With this design, wood chips are removed upward from the cut, leaving a clean and smooth bottom surface of the workpiece. Beey xan, the cutting speed is faster because the chips can be removed efficiently. Up-cut milling cutter can stay sharp longer because chips and dust do not accumulate in the cut. Chéen ba'ale', up-cut milling cutter can cause wear on the top surface of the workpiece.

Up-cut milling cutters are designed for cutting wood, plástico, and aluminum, and this type of milling cutter is often used to produce mortises and deep grooves or blind holes.

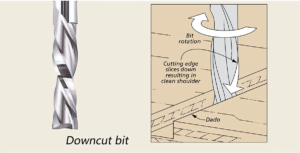

·Down-cut Milling Cutter

Down-cut router bits have a drill bit with grooves running from left to right downward.

Down-cut spiral bits slowly eject wood chips downward, leaving a very clean top edge without wear and chipping. Unlike up-cut spiral router bits that throw wood chips directly out, down-cut spiral router bits require a relatively slow cutting speed because it takes more time to remove these chips. If the down-cut router bit is worked at a very fast speed, the wood chips accumulated in the groove may cause overheating or even damage the drill bit. In wéet k'iin, down-cut spiral router bits become dull faster than up-cut spiral router bits due to the accumulation of chips in the cut.

Down-cut spiral router bits are suitable for creating shallow grooves or mortises in veneer or laminate to prevent tearing of the top surface. It is also ideal for shaping, trimming and pattern cutting. Chéen ba'ale', the bottom edge may wear out as the wood chips move downward and are constantly re-cut.

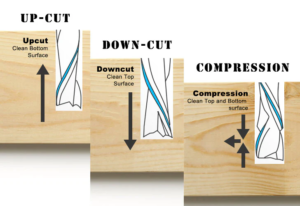

·Compression Milling Cutter

Compression cutting, a combination of upcut and downcut. Tune', it is also called “compression router bit”.

Compared with upcut or downcut, compression router bits can easily leave clean surfaces on the top and bottom of the workpiece: the upcut part quickly pulls out the chips, and the downcut part smoothes the top and bottom edges.

Chéen ba'ale', due to the complex design, compression router bits are more expensive than the other two types. When cutting materials such as plywood, veneer and laminate, compression router bits are definitely the perfect choice to produce clean surfaces on both sides if you have enough budget and know how to use it correctly.

Solid carbide spiral router bits are widely used in the woodworking industry, but only by making the right choice according to the cutting effect requirements can you achieve the ideal effect of the project.

DH Technology Co., Ltd. has been focusing on cutting tools for more than 25 years and can provide you with a wide variety of woodworking or metal cutting tools with various styles, complete sizes and support customized services. If you have any purchasing needs, Ma' dude ti' ts'áik ti' máax ku To'one'.