Woodworking insert blades have transformed workshops by offering unparalleled efficiency and consistent, high-quality results. These innovative blades, characterized by their disposable and replaceable cutting tips, eliminate the downtime and expertise required for sharpening traditional solid blades. This guide will walk you through the essential specifications, Anwendungen, and maintenance practices to help you master their use.

Common Specifications of Insert Blades

Understanding the different specifications of insert blades is the first step to selecting the right one for your project.

* Spiral Insert Heads: These are among the most popular types, featuring multiple insert blades arranged in a spiral pattern around the cutter head. This design allows for a shearing cut, which significantly improves surface finish and reduces noise during operation. They are commonly subdivided into light-cut and heavy-cut versions to handle different material removal demands.

* Heavy-Duty Spiral Heads: Designed for aggressive material removal on machines like automatic copying shapers and four-side planers, these heads feature robust constructions, often with carbon steel bodies, to withstand the forces of heavy cutting and profiling tasks.

* Light-Cut Spiral Heads: Ideal for achieving smooth, planed surfaces on planers and spindle moulder machines, these are optimized for finer finishing work rather than rough lumber processing.

* Indexable Knives for Centrifugal Planers: These systems use small, indexable insert blades that are automatically positioned and secured by centrifugal force. Their key advantage is consistent cutting quality and easy, tool-free replacement, making them a staple in high-volume planing operations where quick changeover is essential.

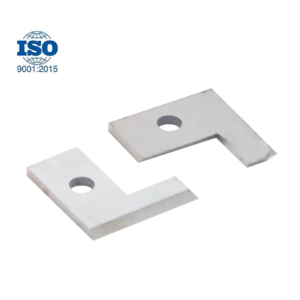

* Solid Carbide Blades: These high-precision insert blades are known for their exceptional sharpness and durability. Made entirely from solid carbide, they are used with CNC router bits and planing knives for superior edge quality and are prized for their long service life and resistance to wear.

Matching the Blade to Your Task and Machine

Choosing the correct blade depends entirely on your desired outcome and the machinery you are using.

* For Smooth Surfacing and Planing: If your goal is to create an ultra-smooth surface on solid wood or panels, a light-cut spiral head on a four-side planer or a double-side planer is an excellent choice. Similarly, indexable knives on centrifugal planers are perfect for high-efficiency finishing on these same machines.

* For Profiling and Shaping: When using a spindle moulder (or shaper) or a CNC machine to create complex profiles, heavy-duty spiral heads or solid carbide profiling insert blades are the tools for the job. They can handle the varying cutting angles and forces involved in shaping the wood.

* For Heavy Stock Removal: For quickly dimensioning rough lumber on a four-side planer, a heavy-cutting spiral head is designed to take deeper, more aggressive cuts without sacrificing the quality of the finish.

Achieving Desired Effects and Practical Applications

The primary benefit of using insert blades is the combination of superior finish and operational efficiency. The spiral design of the most common heads creates a shearing action, which minimizes tear-out, even in tricky grain patterns, and produces very small chips that are easily removed by dust collection systems. This results in a clean, ready-to-finish surface straight from the machine.

These characteristics make insert blades ideal for scenarios where time, Qualität, and consistency are critical. They are extensively used in furniture manufacturing, door and window production, and any professional woodworking environment that processes large volumes of material. The reduced noise level—by as much as 30 zu 50 decibels compared to traditional straight knives—also makes for a much more pleasant and safer workshop environment.

Replacement and Preparation: A Safe and Precise Process

Replacing insert blades is straightforward, but requires care and preparation.

* Preparation: Before starting, always disconnect the machine from power. Gather all necessary tools and a clean, well-lit workspace. Have the correct replacement insert blades on hand and consult the machine’s manual for specific instructions.

* Inspection: Carefully clean the cutter head body, removing any pitch or resin buildup. Before installing a new blade, inspect both the insert blades and the seat in the cutter head for any signs of damage, such as nicks or cracks. Using a damaged component can lead to failure.

* Installation: Handle the sharp insert blades with care, using appropriate gloves. Secure each blade firmly according to the manufacturer’s specifications, ensuring it is properly seated. A loose insert blade is a major safety hazard. After installation, manually rotate the cutter head to check for any obstructions or irregular movements before powering the machine.

Maximizing Lifespan Through Proper Maintenance

Proper maintenance is key to getting the longest life from your insert blades and ensuring consistent performance.

* During Use: Operate the tool at the recommended feed speed and avoid forcing the machine. Consistent, appropriate feed rates prevent overheating and premature dulling. Using the correct type of insert blade for the material (e.g., light-cut vs. heavy-cut) also prevents excessive wear.

* After Use: Post-operation care is crucial. Properly dry the equipment after use and apply a light oil around any screws or moving parts to prevent rust, a practice that is equally important for all cutting tools.

* Storage and Handling: When not in use, store insert blades in a dry, clean place. A dedicated container or original packaging is ideal to protect the sharp edges from damage and prevent rust. Avoid any impact or collision, as these super-hard materials can be brittle.

* Schärfung: One of the main advantages of insert blades is that they are indexable and disposable, meaning you simply rotate or replace the dull tip instead of sharpening it yourself. Attempting to sharpen them without specialized equipment and expertise will likely damage the blade.

By integrating these five essential tips into your workflow, you can fully leverage the power of insert blades to achieve flawless results, boost your productivity, and ultimately revolutionize your woodworking projects.

10 Zoll Klinge 3*30/35 Elektrisch 12 Und 1/4 Breiter Hobel Holz 13 Zoll Tct Hobelmesser