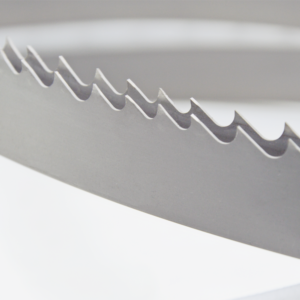

Bi-metal band saw blades are indispensable tools in modern workshops, combining durability with versatility. These blades are engineered through an electron-beam welding process that joins a high-speed steel (HSS) tooth edge to a flexible alloy steel back. This construction delivers the cutting performance of hardened steel while maintaining the flexibility and fatigue resistance necessary for continuous operation. Understanding the differences between woodworking and metal-cutting varieties, their specifications, and proper maintenance is crucial for optimal performance.

Woodworking vs. Metal-Cutting Bi-Metal Band Saw Blades

The fundamental difference between blades designed for wood and metal lies in their tooth geometry, material composition, and intended application.

Woodworking bi-metal band saw blades typically feature larger, more aggressive teeth with deeper gullets. This design facilitates efficient chip removal when cutting softer materials like lumber, madera contrachapada, or plastics. The tooth geometry is optimized for faster feed rates and rapid material removal. Common specifications for woodworking blades often include a lower number of teeth per inch (ITP)—typically ranging from 3 a 6 TPI for thicker stock—which helps prevent clogging with soft materials. The high-speed steel used in the teeth is often a tough grade, resistant to the abrasive silica found in woods.

Metal-cutting bi-metal band saw blades, conversely, are designed for the rigors of cutting ferrous and non-ferrous metals. They generally have a higher TPI count—often between 6 y 24 TPI—to ensure multiple teeth are in contact with the workpiece. This provides stability and reduces vibration, resulting in a smoother cut on hard materials. The high-speed steel used for the teeth is often a higher-grade material like M42, which offers superior heat resistance and wear characteristics crucial for cutting metals like steel, iron, and alloys. For exceptionally hard materials like nickel-based alloys or hardened steel, specialized blades may even utilize advanced powder metallurgy steels like M51.

Selecting the Right Blade for the Job

Choosing the appropriate bi-metal band saw blades is critical for efficiency and blade life. The selection primarily depends on two factors: the material type and its size or shape.

For cutting wood and softer materials, a blade with a lower TPI and larger tooth gullet is ideal. A general rule is to ensure that between 3 a 6 teeth are in contact with the workpiece at any point. This prevents tooth strippage and ensures efficient chip evacuation.

For cutting metals, the TPI must increase with the hardness and thickness of the material. Thin-walled tubes, sheet metal, and hard alloys require a finer pitch (higher TPI—e.g., 18-24) to avoid tooth breakage and achieve a clean cut. Softer metals like aluminum and thicker solid bars can be cut effectively with a medium or coarse pitch (e.g., 10-14 TPI or 6-10 TPI respectively). For cutting iron blocks and steel bars, a blade with a variable pitch tooth pattern is often advantageous as it helps dampen vibration and reduces noise during cutting.

Always match the blade width to the cutting task. Wider blades are more stable for straight cuts in large material, while narrower bi-metal band saw blades are essential for curved or contour cutting.

Proper Maintenance and Break-in Procedures

The longevity of the bi-metal band saw blades are heavily influenced by proper break-in and ongoing care.

Break-in: A new blade requires a careful break-in period to condition the sharp tooth edges. Start by using approximately half the normal feed pressure and about 80% of the recommended speed. Use this setting to cut a surface area of 300-1000 cm². This gentle process smoothes micro-imperfections on the cutting edges, preventing premature dulling and maximizing the blade’s potential service life. A properly run-in blade can last up to three times longer than one that was not.

Cooling and Lubrication: Using the correct cutting fluid is essential, especially for metals. It reduces heat, lubricates the cut, and improves chip removal. The concentration depends on the material; for carbon steel, a more diluted mix can be used, while stainless steel requires a richer concentration to prevent work hardening.

Operational Best Practices:

* Tension: Ensure the blade is tensioned correctly according to the saw manufacturer’s guidelines. Under-tensioning leads to inaccurate cuts and potential blade breakage, while over-tensioning can prematurely fatigue the blade back.

* Guides: Keep the blade guide bearings and thrust wheels adjusted close to the workpiece for maximum support and accuracy.

* Brush: Ensure the chip brush rotates correctly to clean chips from the blade teeth before they re-enter the workpiece, which can cause premature wear.

En conclusión, bi-metal band saw blades are a superior choice for both woodworking and metal-cutting due to their durability and performance. Selecting the right blade involves careful consideration of the tooth pitch and design for the specific material. Furthermore, a dedicated break-in procedure and consistent maintenance regimen are not just recommendations—they are essential investments that dramatically extend blade life, ensure cut quality, and ultimately improve productivity in any workshop. By understanding these key principles, you can maximize the value and performance of your bi-metal band saw blades.