Quando si usa una band sega lama, Il raggiungimento del taglio perfetto dipende non solo dalla potenza della macchina, ma anche sulla scelta della lama destra e sulla garanzia di una spaziatura ottimale dei denti.

Sia che tu stia lavorando con il legno, metallo, o plastica, the correct tooth spacing on your band saw blade has a direct impact on the smoothness and accuracy of your cuts. Understanding tooth pitch can significantly improve cutting results and reduce band saw blade wear.

Why is tooth pitch important?

Tooth pitch, or teeth per inch (TPI), is critical in balancing cutting performance and band saw blade life.

The correct TPI ensures you have enough teeth in contact with the material, improving cutting accuracy for a clean cut without overloading the band saw blade.

By choosing the right TPI for your material, the blade can easily handle a variety of materials, produce smoother cuts, and help prevent problems like rough edges, blade wear, and overheating. This makes your cutting process faster, more cost-effective, and overall safer.

Choosing the wrong tooth pitch will cause various problems.

·Using too few teeth: results in a rough cut and may cause excessive stress on the band saw blade, shortening its life.

·Using too many teeth: Overloading the blade and causing it to overheat, leading to premature wear and inefficient cutting.

·Ignore material thickness: If the TPI does not match the material thickness, damage to the band saw blade and workpiece may occur.

What is the difference between the two types of tooth pitch?

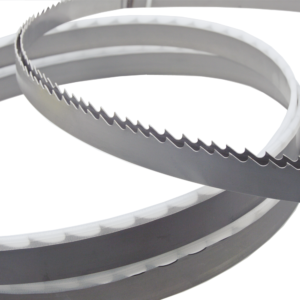

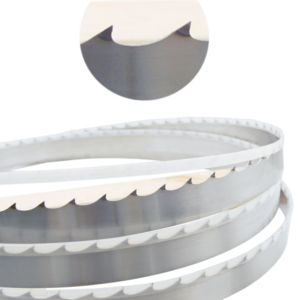

Tooth pitch is divided into constant pitch and variable pitch. A constant pitch means that the distance from one tooth tip to the next is uniform, while a variable pitch band saw blade has a tooth pitch that is within a set of teeth.

Constant pitch saw blades increase harmonic vibrations. Harmonic vibration can cause excessive noise, undesirable vibrations in the saw blade, and in severe cases, poor cutting results.

Variable pitch band saw blades have varying tooth groove depths, tooth pitch angles, and tooth spacing, which can greatly reduce harmonic vibrations. This is especially effective when cutting odd-shaped materials that are more prone to vibration.

The variable tooth set also helps reduce tooth spalling that occurs when cutting hard materials. It also has high heat, abrasion and impact resistance. These factors allow for a wider range of applications when cutting metal.

How to choose the correct band saw blade tooth pitch?

For optimal cutting results, it is crucial that the type and thickness of material being processed matches the tooth pitch. This determines which blade is suitable for the job and how many teeth should be in contact with the material during the cut.

Primo, we need to understand that industry standards state that each cut should have a minimum of 3 teeth and a maximum of 24 denti. Optimally, you should have 6 A 12 teeth per cutting operation. Following this rule ensures a balance between cutting speed and blade life, avoiding problems such as jagged edges or overloading the blade.

A general rule of thumb for serrations is: The greater the TPI, the smoother but slower the cut; the less or lower the TPI, the rougher but faster the cut.

Depending on the material being processed, softer materials require fewer cutting teeth but have greater tooth space capacity. The processing of harder materials requires more cutting teeth to share the machine’s capacity load, but the tooth space area is smaller.

·For general wood cutting:

Cutting should be done using coarse-tooth blade settings—2-TPI and 3-TPI.

·For thinner metals and plastics: A fine-tooth blade setting should be used — 18 A 32 TPI.

You also need to consider the thickness of the material.

·Thin materials (less than 1/4 inch): 18-24 TPI

·Medium thickness (1/4 A 1/2 inch): 14-18 TPI

·Thick material (1/2 A 1 inch): 10-14 TPI

·Very thick materials (over 1 inch): 6-10 TPI

Hopefully this short article will help provide a better understanding of TPI and its impact on production. Properly combine the specific type and size of material when selecting a TPI saw blade to ensure high-quality output.

If you have more insights and related experiences about TPI, please leave a message in the comment area to share. Here is DH Technology Co., srl, which has been committed to providing high-quality cutting tools.