목공 카바이드 인서트 블레이드는 목공 기계의 표준 지원 도구가 되었습니다..

보다 효율적이고 정밀한 목공 블레이드는 더 많은 목공 프로젝트를 생산하고 비용을 절감할 수 있습니다., 가장 일반적으로 사용되는 것은 목재 절단용 텅스텐 카바이드 인서트 블레이드입니다..

하지만 그렇다고 해서 선택지가 하나뿐이라는 뜻은 아닙니다. 사실은, there was a flat knife that was very popular among manufacturers many years ago. But why is it so difficult to see traditional flat knives in factories or personal workshops now?

There is a reason for this.

1. Traditional flat knives will produce burn marks. When used for a long time, the cutting edge becomes dull, or when feeding is temporarily stopped, the cutting heat will leave burn marks on the surface.

2. The temperature distribution performance of traditional flat knives is poor. When the tool becomes hot during operation, the blade will also bear higher heat, and its passivation speed will be accelerated, which may cause the tool to lose its original stability.

3. Traditional flat knives can easily cause large damage marks on wood. Due to the large force-bearing area of traditional flat knives, it is easy to cause cutting deformation and uneven cutting surfaces.

4. Difficulty in chip removal: The wood chips after cutting with the flat knife are larger. In the central integrated system, oversized wood chips cannot be discharged in real time, causing the processed wood chips to affect the processing quality.

The design principle of carbide insert blades for wood improves the shortcomings of the above-mentioned flat knives and increases the convenience of cutting:

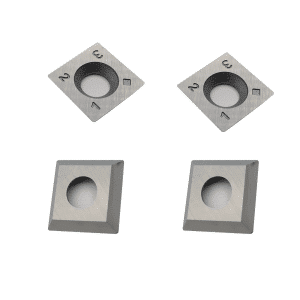

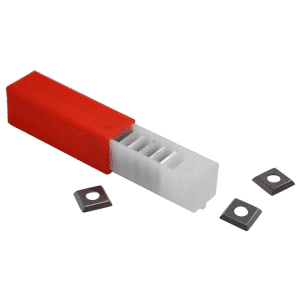

High-quality carbide insert blades for wood use ultra-fine grain carbide grades, and the finished product has the characteristics of high toughness and high strength.

1. Spiral blade surface: The tungsten carbide wood cutting knife will not produce burn marks on the cutting surface, which improves the undesirable situation of blade burns and tearing knife marks caused by flat knives.

2. Fast heat dissipation: The carbide insert blades with aluminum alloy body has better heat dissipation effect, and the tungsten carbide blade shows extremely strong stability and ensures a longer service life.

3. The wood chips are extremely small: The wood chips formed by spiral cutting per unit time are extremely small, and it is easy to discharge the wood chips away from the wood surface in the central integrated system.

4. Low noise: The noise value generated when the wood surface and the flat knife are in contact with the wood surface at the same time is about 70% lower.

All in all, there are so many advantages that make us choose tungsten carbide insert blades for woodworking. There may be some people who use traditional knives who still think traditional knives are better. I couldn’t agree more. But with the progress of the times and the development of technology, more things will become obsolete. Not because they don’t have advantages, but because we have better options.

DH Technology Company has been engaged in manufacturing and exporting high-quality woodworking tools for more than 24 연령. It has a rich range of woodworking cutting tool products and can provide customized services for specialized woodworking projects. 당신이 우리의 제품에 관심이 있다면, 언제든지 연락 주시기 바랍니다!

10 인치 블레이드 3*30/35 전기 같은 12 그리고 1/4 와이드 플레이너 우드 13 인치 Tct 플레이너 블레이드