In the demanding world of industrial cutting, where productivity grinds to a halt with every broken or dulled blade, one solution stands resilient against the toughest challenges: the Stellite band saw blade. This remarkable tool redefines durability and performance, offering a lifeline for operations plagued by premature blade failure. When conventional blades quickly succumb to heat, abrasion, and shock, the unique properties of a Stellite band saw blade provide a reliable, long-lasting cutting partner for the most difficult materials, from hardened alloys to dense hardwoods.

The Heart of Resilience: Composition and Craftsmanship

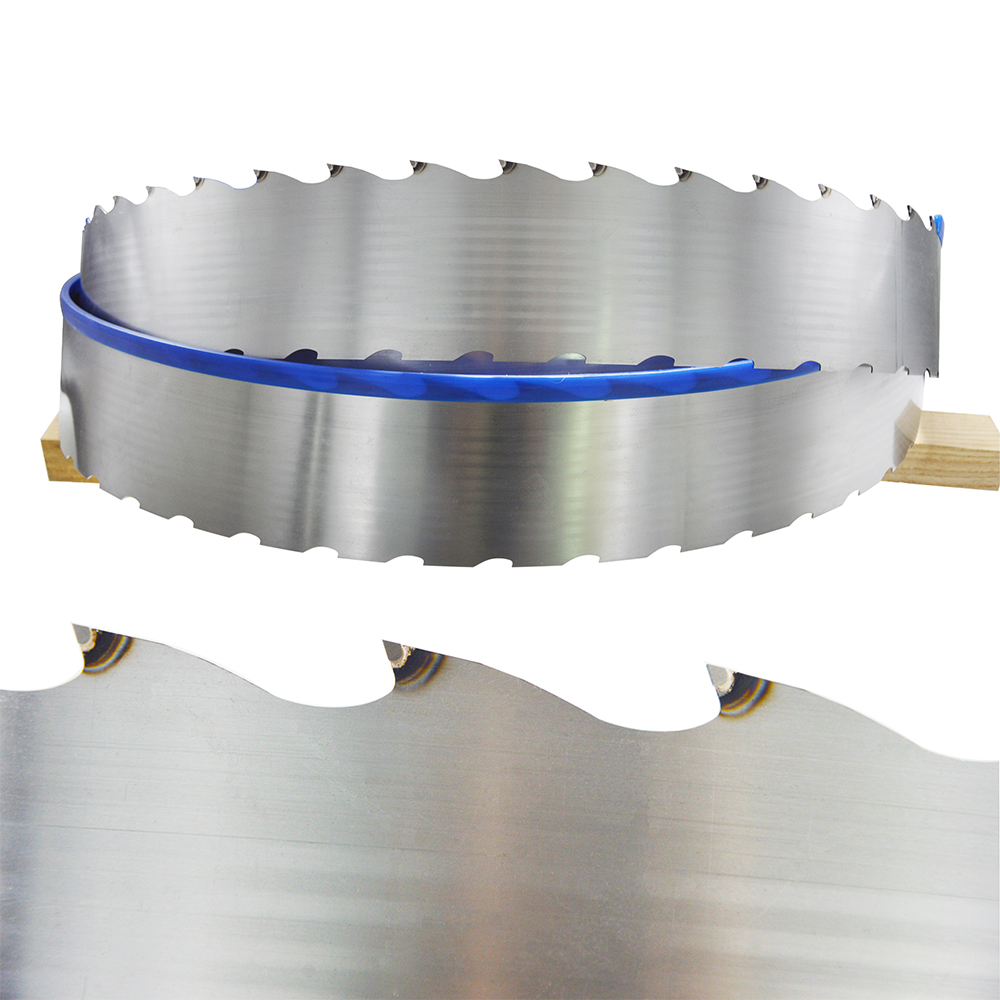

A Stellite band saw blade is an engineering marvel, a composite tool designed for extreme service. Its foundation is a high-strength alloy steel backer, providing the necessary flexibility and tensile strength to withstand the immense forces and continuous flexing within a band saw machine.

The true cutting magic, 하지만, resides in the teeth. These are not merely sharpened steel. Instead, precision-formed tooth tips are made from Stellite alloy—a family of cobalt-chromium-based superalloys renowned for their exceptional properties. In a specialized welding process, often using precision techniques like laser or TIG welding, these Stellite tips are securely bonded to the steel body. The teeth are then carefully set, sharpened, and finished, resulting in a blade where unparalleled wear resistance meets rugged flexibility.

Mastering the Unforgiving: Performance and Prime Applications

The Stellite band saw blade excels where other blades fear to tread. Its supreme advantage is maintaining a sharp cutting edge under conditions that rapidly destroy standard blades: intense heat, severe abrasion, and intermittent cutting. This translates into the ability to cleanly cut through a host of problematic materials.

Key applications include slicing through hardened steels, heat-treated alloys, tough stainless steels, abrasive cast irons, nickel-based superalloys, and even certain titanium alloys. The Stellite band saw blade delivers consistent, straight cuts with a good surface finish in these materials, dramatically reducing downtime for blade changes and keeping production flowing on difficult jobs.

https://dhcutter.net/product-category/stellite-band-saw-blade/page/13/

https://dhcutter.net/product-category/stellite-band-saw-blade/page/13/

A Timber Champion: Conquering European Oak

Beyond metalworking, the Stellite band saw blade has earned legendary status in a particularly demanding arena: milling high-value hardwoods, most notably European Oak. Oak’s combination of density, inherent silica content, and often unpredictable grain structure makes it notoriously abrasive and prone to causing rapid dulling in conventional bimetal or carbide-tipped blades.

Here, the Stellite band saw blade proves its unparalleled superiority. Its exceptional resistance to abrasion allows it to slice through oak with sustained sharpness, producing smoother cuts with less burn and far superior edge retention over thousands of feet. This results in less waste, higher yield from expensive lumber, and dramatically fewer production stoppages for blade changes. It is no wonder that this blade has become the undisputed, best-selling choice for high-output sawmills and precision furniture manufacturers across Europe, where oak is king and efficiency is paramount.

Stellite Band Saw Blade vs. TCT 밴드 톱날 : A Battle of Strengths

While Tungsten Carbide Tipped (TCT) blades are known for extreme hardness in ideal conditions, the Stellite band saw blade offers a different, often more practical, set of superpowers for real-world shop floors. The primary distinction lies in material properties. Carbide is extremely hard but also brittle, making it susceptible to chipping from vibration, shock, or inconsistent feed rates—a common issue with irregular materials like wood with knots or embedded debris. 스텔라이트, in contrast, possesses outstanding hot hardness—it actually gets harder as it heats up during cutting—and superior impact resistance.

This gives the Stellite band saw blade critical advantages. 첫 번째, it is far more forgiving. It can handle the intermittent cutting of irregular shapes (like castings, forgings, or knotty timber), bundled material, and even slight operator variances without catastrophic tooth failure. Second, its thermal resilience means it performs consistently where cooling is difficult or on materials that generate intense friction heat. For a versatile, day-in-day-out blade that tackles a mixed bag of tough materials without babying, the Stellite band saw blade is often the more robust and cost-effective champion.

Guardian of the Edge: Maximizing Blade Life

To ensure your Stellite band saw blade delivers its full, legendary lifespan, attentive maintenance and operation are key. Follow these essential practices:

Break-In with Care: Begin with light feed pressure for the first 50-100 square inches of cut area. This gently conditions the cutting edge, preventing micro-fractures and establishing a long-lasting wear pattern.

Match Speed and Feed: Always use the machine manufacturer’s recommended band speed (SFPM) and apply firm, consistent feed pressure. Letting the blade rub without cutting generates excessive heat, while forcing it too hard can cause tooth strippage.

Use Proper Lubrication/Coolant: For metalworking, a high-quality coolant is non-negotiable. For woodcutting, ensuring proper blade lubrication (where applicable) and chip removal is vital to manage heat and resin buildup.

Ensure Machine Health: A poorly maintained saw is a blade killer. Regularly check and adjust band wheel alignment, guide arms, and bearings. Even the best Stellite band saw blade will fail quickly on a machine with excessive vibration or misalignment.

Clean and Store Smartly: 사용 후, clean the blade of chips, 정점 (for wood), or residue. For storage, relieve tension and consider applying a light protective oil. Store blades appropriately to avoid damage.

By treating this powerful tool as a partner rather than a consumable, you unlock its full potential, transforming your most challenging cuts from a constant struggle into a routine success.