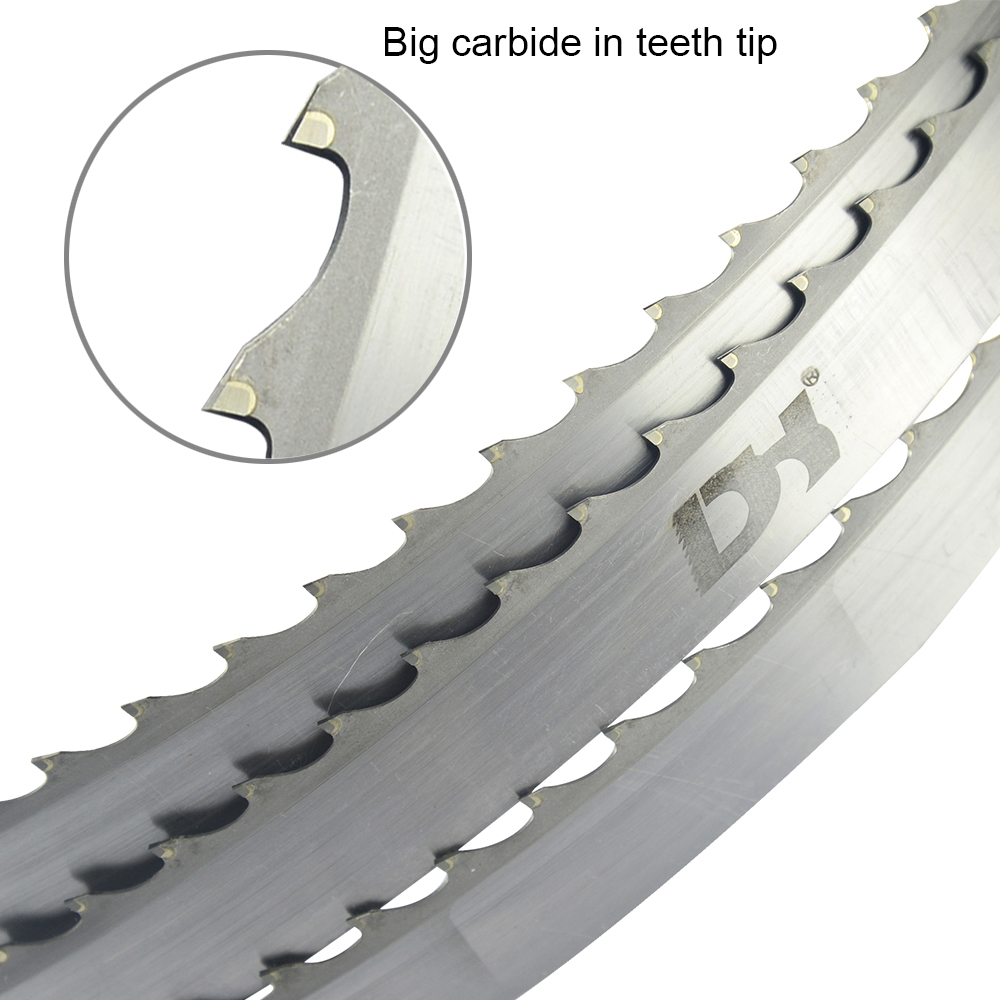

Product Introduction

Horizontal | Vertical | |

Material | Tungsten Carbide | Tungsten Carbide |

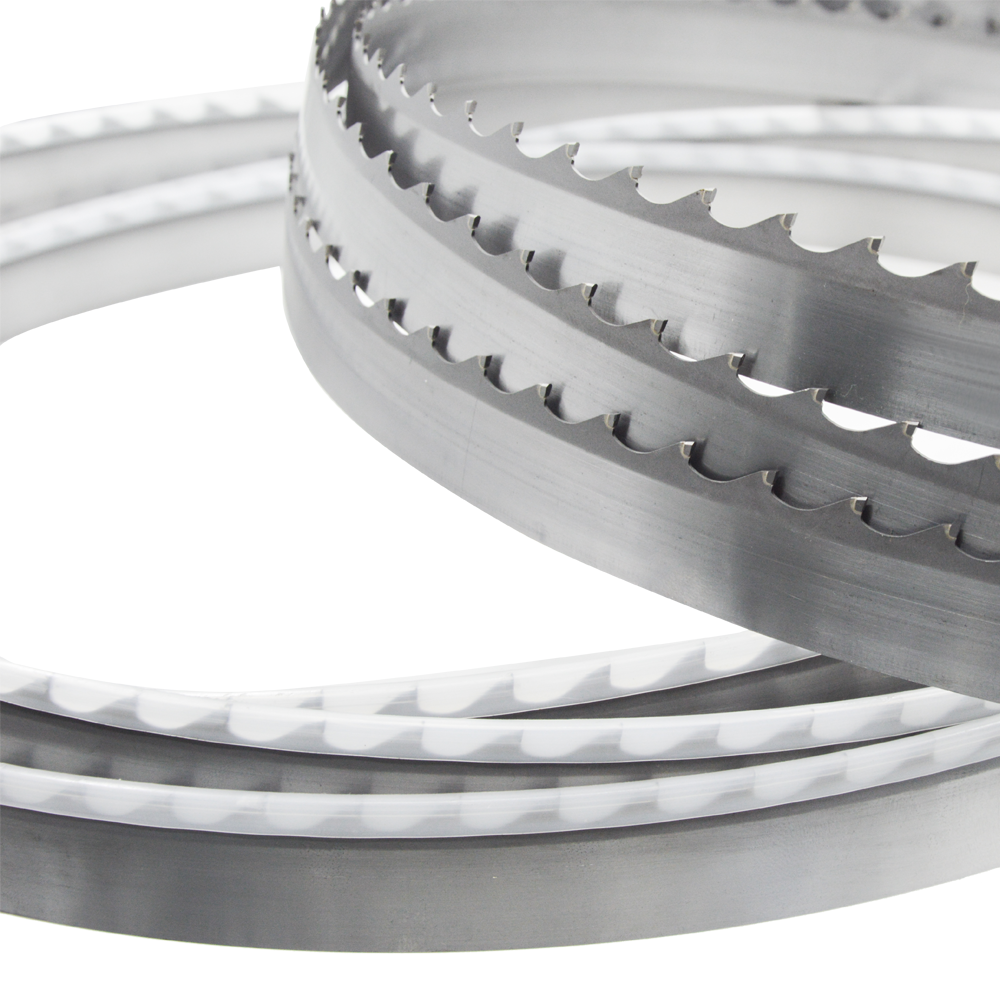

TPI | 15-50mm | 13-60mm |

Application | Wood | Wood |

Length | 3500-12000mm | 3500-15000mm |

Thickness | 0.7-1.5mm | 0.7-1.67mm |

Width | 27-150mm | 15-260mm |

Kerf | 1.3-3.0mm | 1.3-3.2mm |

Type | Woodworking | Woodworking |

Note: Customized service available |

Possible Problems & Solutions

PROBLEM :The surface of the cut board is uneven and deviatesREASON①: Deformation of the wheel surface

PREVENT/SOLVE①: the saw blade rubs against the wheel surface for a long time, and the wheel surface is not trimmed

REASON②: Rolling treatment is not good

PREVENT/SOLVE②: problems in the production of saw blades

REASON③: Angle mismatch

PREVENT/SOLVE③: production process problem, provide specific gravity of cut wood to production

REASON④: The knife

edge is not sharp

PREVENT/SOLVE④: it has not been ground for a long time

REASON⑤: Improper clamp (head) adjustment

PREVENT/SOLVE⑤: excessive clamp clearance

PROBLEM: Saw Blade crackedREASON①: Material Issues PREVENT/SOLVE①:Production Issues

REASON②:The knife edge is not sharp and the resistance is too large PREVENT/SOLVE②:the single use time is determined according to different materials to be cut

REASON③:Tooth profile mismatch PREVENT/SOLVE③:production problem

REASON④:Repair Grinding Cause PREVENT/SOLVE④:Incorrect Grinding

REASON⑤:Bad rolling handling PREVENT/SOLVE⑤:production problem

REASON⑥:Improper blade cooling PREVENT/SOLVE⑥:not cooling properly, or not cooling the bladeproperly

PROBLEM: Saw Blade breakREASON①: Material reason PREVENT/SOLVE①:production problem

REASON②:The knife edge is not sharp, and it has :been used for too long,and the resistance is too large PREVENT/SOLVE②: grind it on time

REASON③:The saw blade is rubbing against the equipment PREVENT/SOLVE③:adjust until the saw blade fits perfectly with the equipment

REASON④:Too much tension PREVENT/SOLVE④:choose thecorresponding tension according to the width and thickness of the saw blade

REASON⑤:The feed speed does not match

PREVENT/SOLVE⑤:according to the cutting of different wood, give the corresponding feed speed

REASON⑥:Human factors PREVENT/SOLVE⑥:wood ash notcleaned in time, grinding is not precise enough, manual feeding speed is uneven, key parts of the machine are regularly lubricated

Packaging & Shipping

Company Introduction

Why Choose Us

Contact Information

Contact Person | Emma |

WhatsApp/ Phone Number | +86 13825289615 |

WeChat | DHcutter |

E-mail Account |

Related Products

Band Saw Blade | Circular Saw Blade | End Milling Cutter | Drill Bit | Finger Joint Cutter |

Helical Spiral Cutter | Cutter Head | Planer Knife | Grinding Wheel | Woodworking Machine |

Reviews

There are no reviews yet.