For woodworkers seeking to enhance their joinery skills, the finger joint cutter is a versatile and powerful tool. This specialized bit opens up a world of strong and decorative possibilities. Whether you’re crafting boxes, drawers, or furniture, mastering this cutter allows you to create interlocking joints that are both durable and visually appealing. This comprehensive guide will walk you through its uses, selection, operation, and care, ensuring your projects reach a professional standard every time.

When to Use a Finger Joint Cutter – Needs, Effects, and Scenarios

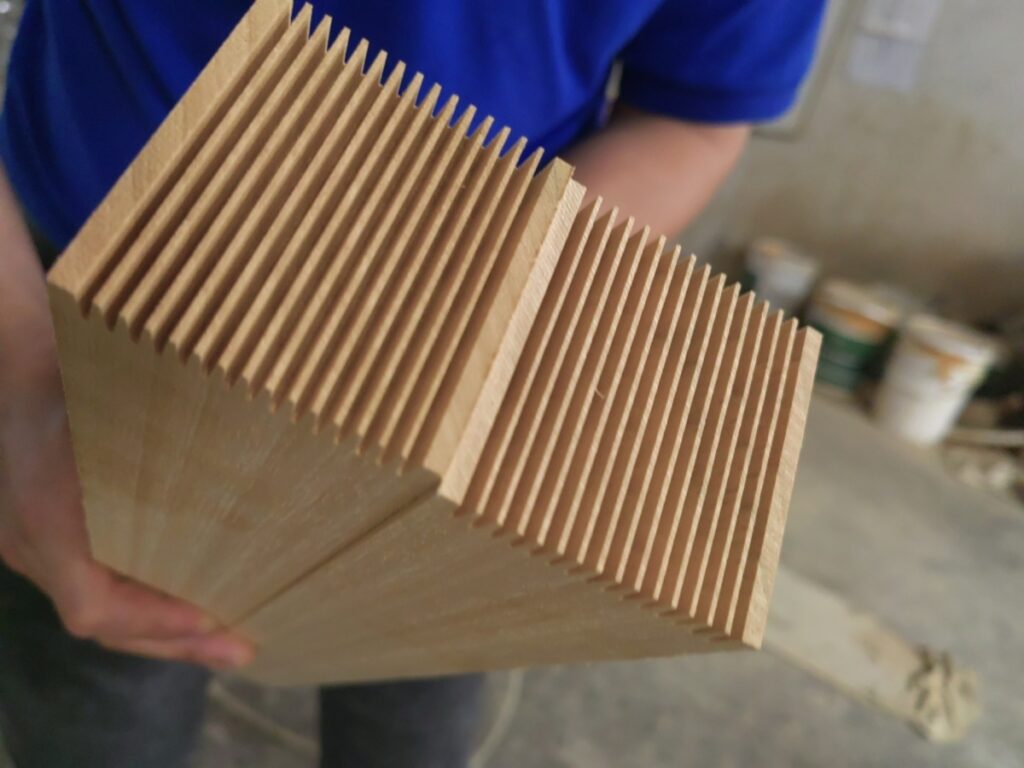

The primary use of a finger joint cutter is to create finger joints, also known as box joints. These joints consist of complementary, interlocking rectangular fingers cut into the ends of two wood pieces. You should reach for this tool when your project demands a joint far stronger than a basic butt joint.

Consider using a finger joint cutter for constructing drawer boxes, cabinet corners, or picture frames. In these applications, the large gluing surface area created by the meshing fingers results in an extremely robust bond. This makes the joint ideal for items that will bear weight or withstand frequent use.

Beyond pure strength, the finger joint cutter also creates a distinct and attractive pattern. This makes it perfect for decorative boxes, small chests, or any project where you want the joinery itself to be a visible design feature. The repeating pattern adds a handcrafted, mechanical beauty to your work.

Another excellent scenario for this tool is wood waste reduction. A well-setup finger joint cutter allows you to seamlessly join shorter board offcuts into longer, usable panels. This technique is invaluable for maximizing material and creating unique laminated pieces for tabletops or panels.

Konečne, for any production work requiring multiple identical joints, the finger joint cutter excels. Once your router table or jig is precisely calibrated, you can reproduce perfect joints quickly and consistently. This efficiency is a key reason the finger joint cutter is a staple in many workshops.

Preparations Before Purchase and Common Specifications

Choosing the right finger joint cutter requires some forethought. Your first step is to assess your common project sizes. The scale of your work—from delicate jewelry boxes to substantial bookshelves—will directly determine the appropriate finger size you need.

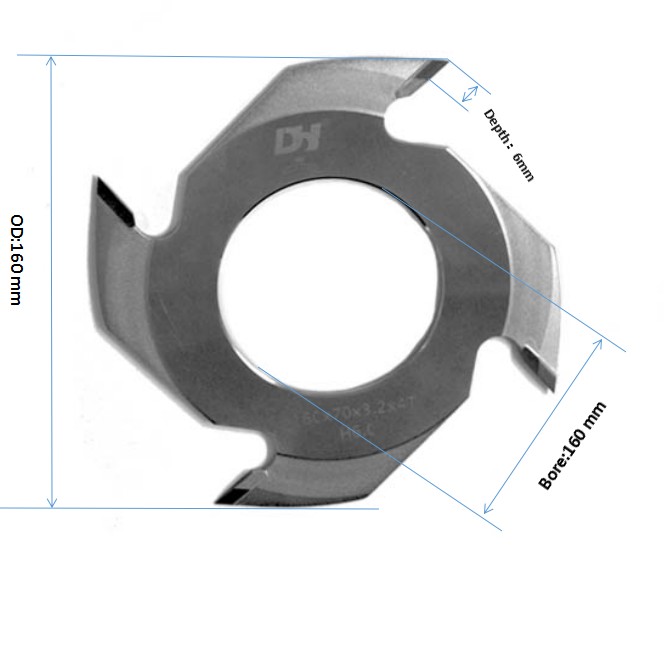

Ďalšie, confirm your tool’s compatibility. Most finger joint cutters are designed for use in a router table, which provides the necessary control and safety. You must check the shank diameter to ensure it fits your router’s collet. Tiež, verify that your router can operate at a suitable speed for the cutter’s diameter.

Familiarize yourself with the common specifications available. Finger joint cutters are typically categorized by the size of the fingers they produce. A 1/4-inch finger joint cutter is a popular choice for fine, detailed work. It creates a delicate joint perfect for small crafts and boxes.

For a great all-around option, a 3/8-inch finger joint cutter offers an excellent balance. The fingers are substantial enough for strong furniture joints while remaining visually pleasing on mid-sized projects like drawers and small cabinets.

When strength is the paramount concern, such as for workbenches or structural frames, a 1/2-inch finger joint cutter is the heavy-duty choice. The larger fingers create a massive gluing area, resulting in an exceptionally durable connection.

You may also encounter adjustable finger joint cutters. These allow you to modify the width of the fingers, offering great flexibility for custom projects. Avšak, fixed-size cutters often provide greater precision and rigidity for repeated tasks.

Important Considerations During Use

Safe and accurate operation of a finger joint cutter is non-negotiable. Always begin with personal protective equipment. Safety glasses and hearing protection are mandatory, and dust collection is highly recommended to maintain visibility and lung health.

Workpiece security is critical. The wood must be firmly held against a fence and a sacrificial backing board using featherboards and push blocks. This prevents kickback and ensures your hands remain a safe distance from the spinning cutter. Never attempt to cut small pieces without proper jigging.

A test cut on scrap wood from the same stock is an absolute must. This allows you to fine-tune the height of your finger joint cutter and the position of your fence. The goal is to achieve fingers that mesh together snugly without being too tight or too loose.

During the cut, feed the wood at a steady, controlled pace. Rushing can lead to tear-out, burning, or an uneven joint. It can also overheat and damage the cutter. A naopak, feeding too slowly increases friction and the risk of burning the wood.

For perfect alignment, it is crucial to use a consistent reference face against the fence for all related pieces. Marking your workpieces clearly can help avoid confusion. Pamätajte, one board’s “finger” must become the other board’s “gap,” so systematic cutting is key to success.

Always ensure your router is running at the speed recommended by the finger joint cutter’s manufacturer. A clean, sharp cutter running at the correct speed will produce the cleanest cuts with the least effort and risk.

Maintenance for Longevity

Consistent maintenance is the secret to a long-lasting finger joint cutter. The first and most important habit is immediate cleaning after use. Use a dedicated soft-bristle brush to dislodge all wood resin and dust from the cutting edges. Sticky residue left on the cutter can harden and impair performance.

After brushing, wipe the cutter gently with a clean, dry cloth. Avoid using harsh solvents or abrasives that could damage the carbide tips or the tool’s body. If necessary, a small amount of specialized router bit cleaner can be used, but always follow the product instructions.

Proper storage is your next line of defense. Always store the finger joint cutter in its original protective case or a dedicated bit holder. This protects the sharp edges from accidental contact with other tools, which can cause nicks and dulling.

Moisture is an enemy of all steel tools. Store your cutter in a dry environment. If it ever gets wet, dry it thoroughly before putting it away. A light coating of a rust-inhibiting spray can be applied for long-term storage, but ensure it is completely removed before next use.

Regularly inspect the cutting edges under good light. Hľadajte známky tuposti, such as rounded edges or small chips. A dull finger joint cutter requires more force to use, increases the risk of tear-out, and puts unnecessary strain on your router.

When sharpening is required, it is best to entrust a quality finger joint cutter to a professional sharpening service. They have the equipment and expertise to regrind the complex geometry correctly. Attempting to sharpen it yourself can easily ruin its precision and balance.

By following this detailed guide—from selecting the right tool to maintaining it meticulously—you will fully leverage the capabilities of your finger joint cutter. It will become a reliable asset in your workshop, enabling you to build stronger, more beautiful, and more professional woodworking projects for years to come.