Shenzhen Dehuai Technology Co., LTD. ( DH )

Is a professional manufacture engaged in various TCT Band Saw Blade, Frame Saw Blade. We are the manufacturer which have 24 years’ experience in manufacture and sales. The main products are TCT Band Saw Blade, Stellite Band Saw Blade, Bi-metal Band Saw Blade, Teeth Hardened Band Saw Blade and so on. OEM and ODM are acceptable.

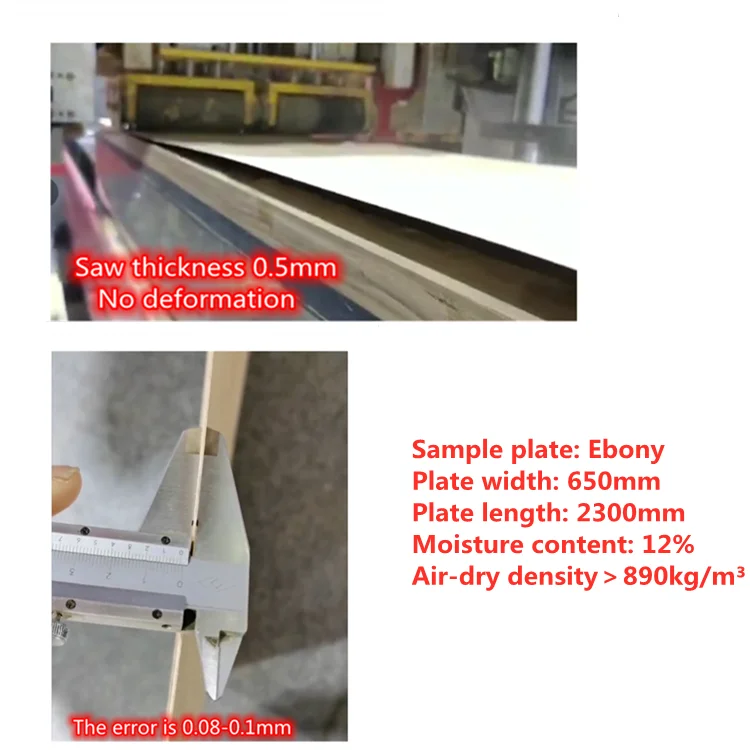

Customize | Available |

Material | Tungsten Carbide |

TPI | 15-45MM (Size Customize) |

Apllication | Wood/Graphite |

Length | 3500-12000MM (Size Customize) |

Thickness | 0.8-2.3MM (Size Customize) |

Width | 13-125MM (Size Customize) |

Kerf | 1.3-2.4MM (Size Customize) |

Hardness | 93.5° |

Customize | Available |

Material | Tungsten carbide |

TPI | 12-45mm (Size Customize) |

Application | Wood/Graphite |

Length | 3200-12000MM (Size Customize) |

Thickness | 0.9-2.6MM (Size Customize) |

Width | 27-150MM (Size Customize) |

Kerf | 1.3-2.4MM (Size Customize) |

Hardness | 93.5° |

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below:

PROBLEM :The surface of the cut board is uneven and deviates

PREVENT/SOLVE: the saw blade rubs against the wheel surface for a long time, and the wheel surface is not trimmed

REASON: Rolling treatment is not good PREVENT/SOLVE: problems in the production of saw blades

REASON: Angle mismatch PREVENT/SOLVE: production process problem, provide specific gravity of cut wood to production

REASON: The knife edge is not sharp

PREVENT/SOLVE: it has not been ground for a long time

REASON: Improper clamp (head) adjustment

PREVENT/SOLVE: excessive clamp clearance

PROBLEM: Saw Blade cracked

REASON:The knife edge is not sharp and the resistance is too large PREVENT/SOLVE:the single use time is determined according to different materials to be cut

REASON:Tooth profile mismatch PREVENT/SOLVE:production problem

REASON:Repair Grinding Cause PREVENT/SOLVE:Incorrect Grinding

REASON:Bad rolling handling PREVENT/SOLVE:production problem

REASON:Improper blade cooling PREVENT/SOLVE:not cooling properly, or not cooling the blade properly

PROBLEM: Saw Blade break

REASON:The knife edge is not sharp, and it has :been used for too long,and the resistance is too large PREVENT/SOLVE: grind it on time

REASON:The saw blade is rubbing against the equipment PREVENT/SOLVE:adjust until the saw blade fits perfectly with the equipment

REASON:Too much tension PREVENT/SOLVE:choose thecorresponding tension according to the width and thickness of the saw blade

REASON:The feed speed does not match

PREVENT/SOLVE:according to the cutting of different wood, give the corresponding feed speed

REASON:Human factors PREVENT/SOLVE:wood ash notcleaned in time, grinding is not precise enough, manual feeding speed is uneven, key parts of the machine are regularly lubricated

1.We have 24 years experience in Cutting Tools.

2.We are industry and trade integration, provide reasonable price for you.

3. Professional research team and sales team.4. We have our own factory.5. All products are 100% tested working before sending to you .6. Quick delivery.7. OEM and ODM are acceptable.

Packaging

In carton or any other packaging as your request.

Shipping

Usually we will quote you the most reasonable shipping method according to your country, good types, weight and reqested delivery time.We shall appreciate if you could write us details of your order quantity, country, sea port/air port before you send us inquiry. In this way we can offer you the best and most accurate price.Payment

Accept payment by T/T, Alibaba Payment, L/C.Delivery

5-10 days after order confirmed.

Contact Person | Sophia |

WhatsApp/Phone Number | +86 15889650828 |

WeChat | dehuaicutter |

E-mail Account |

Reviews

There are no reviews yet.