For modern woodworkers, carbide insert blades have revolutionized the craft, offering exceptional durability, precision, and cost-effectiveness. Unlike traditional all-steel blades, these cutting tools feature replaceable carbide tips (inserts) brazed or mechanically fastened onto a steel body. The exceptional hardness of carbide — significantly higher than high-carbon steel — allows these blades to maintain sharpness up to 10 times longer, even when processing abrasive hardwoods, Laminados, or composite materials. This guide explores the main types of carbide insert blades for woodworking, addresses common operational challenges, and outlines best practices for maximizing their performance and lifespan.

Primary Types of Carbide Insert Blades in Woodworking

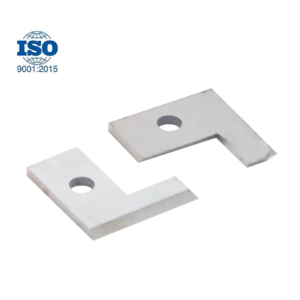

- Planer and Jointer Blades: These are typically straight carbide insert blades used in surface planing and jointing operations. Multiple inserts are mounted on a cutter head, enabling individual rotation or replacement when one segment becomes damaged or dull. This design drastically reduces material waste and replacement costs compared to solid blades.

- Router Insert Blades: Used with CNC routers or handheld routers, these carbide insert blades come in countless profiles (round-over, cove, ogee, V-groove, etc.). The inserts are designed for specific cuts, allowing complex shaping without requiring the entire blade to be resharpened.

- Saw Blades with Carbide Inserts: While most circular saw blades use brazed carbide teeth, larger industrial saws (like those used in panel processing) sometimes utilize mechanically fastened carbide inserts. These are common in high-wear applications like cutting MDF or melamine-coated particleboard.

- Moulder Knives with Carbide Inserts: For producing mouldings, window components, or door parts, moulders use cutter heads fitted with profiled carbide insert blades. The inserts withstand the high linear speeds and volumes associated with these machines.

- Specialty Shaper Cutters: Similar to router bits but typically larger and more robust for spindle shapers, these cutters often incorporate replaceable carbide inserts for heavy-duty edge profiling and joinery tasks.

Five Common Problems with Carbide Insert Blades and Their Solutions

- Premature Insert Wear or Chipping:

* Problem: Carbide is hard but brittle. Inserts can chip at the cutting edge or wear down faster than expected, leading to poor surface finish (tear-out, burning) and increased cutting resistance. This is often caused by improper feed rates (too slow causes friction burning; too fast causes impact chipping), cutting overly abrasive materials, or hitting foreign objects (nails, knots).

* Solution: Match the feed rate and spindle speed to the material and cutter diameter. Reduce feed rates for very hard or knotty wood. Ensure inserts are securely fastened and the correct insert grade (e.g., micro-grain for finer cuts, tougher grades for abrasive materials) is used. Inspect stock for embedded metal. Rotate inserts regularly to distribute wear evenly .

- Vibration and Poor Surface Finish:

* Problem: Excessive vibration (chatter) during cutting results in visible ripple marks or an uneven surface on the workpiece. This can stem from incorrect installation causing imbalance (e.g., inserts not seated properly or at differing heights), a dull or damaged insert, excessive cutter projection, or machine issues (worn bearings, inadequate rigidity).

* Solution: Meticulously clean the blade body pocket and the insert seat before installation. Use a setting gauge or dial indicator to ensure all inserts project exactly the same amount from the cutter body. Check and tighten all clamping screws/bolts to the manufacturer’s specifications. Verify machine spindle bearings and tool holders are in good condition. Ensure the workpiece is firmly secured using appropriate clamps or fixtures to prevent movement .

- Insert Breakage or Pulling Out:

* Problem: Inserts can fracture completely or become dislodged from the blade body during operation. This is extremely dangerous and usually caused by excessive cutting forces (too deep a cut, too fast a feed), an undersized or damaged clamping mechanism, incorrect installation (dirty seat, insufficient torque), or severe impact.

* Solution: Strictly adhere to recommended depth-of-cut limits per pass. Never force the tool through the material. Always use the correct torque wrench to tighten clamping screws/bolts as specified by the manufacturer. Regularly inspect screws/bolts and clamping mechanisms for wear, damage, or stretching, and replace them immediately if found. Avoid overloading the tool .

- Poor Chip Removal (Embalaje):

* Problem: Wood chips pack around the cutter head or behind the insert. This creates friction, leading to overheating (which damages the carbide and can cause glue-line issues in laminates), increased load on the machine, and potential fire hazard.

* Solution: Ensure the carbide insert blades are clean and free of resin/pitch buildup before use. Use cutters designed with effective chip clearance geometry. Employ adequate dust collection at the source. Consider using lubricants or anti-pitch coatings on inserts for resinous woods. Adjust feed rates – sometimes a slightly faster feed helps eject chips more effectively .

- Reduced Cutting Accuracy and Dimensional Issues:

* Problem: Workpieces are not cut to the expected size or profile. This can be due to inserts not being set to the correct projection height (causing inconsistent cutting depth), worn or incorrectly seated inserts altering the effective cutting diameter/profile, or deflection caused by excessive cutting forces or machine issues.

* Solution: Always use a precise setting gauge when installing or rotating inserts. Regularly check insert projection heights with a dial indicator, especially after changes. Inspect inserts for wear on the critical cutting edges and flank surfaces. Verify machine calibration and rigidity. Ensure the cutter body itself is not damaged or worn where inserts seat .

Essential Maintenance and Handling Practices for Carbide Insert Blades

* Proper Installation is Paramount: This cannot be overstated. Always clean the insert seat and pocket meticulously – a tiny wood chip or resin speck can cause misalignment. Use the correct tools (torque wrench, setting gauge) and follow the manufacturer’s instructions precisely for tightening sequence and torque values. Incorrectly installed carbide insert blades are a primary cause of failure.

* Regular Cleaning: Alquitrán, resin, and wood sap accumulate on inserts and cutter bodies, affecting balance, heat dissipation, and chip flow. Clean blades promptly after use using appropriate solvents (following safety guidelines) and non-metallic brushes. Avoid abrasive methods that could damage the carbide or coatings .

* Correct Storage: Store carbide insert blades and loose inserts in dedicated, protective cases or organizers. Prevent contact between cutting edges and other hard objects (like other tools or inserts) to avoid chipping. Keep them in a dry environment to prevent corrosion – while carbide itself doesn’t rust, the steel body of the blade and clamps certainly can.

* Handle with Extreme Care: Carbide is brittle. Dropping an insert or blade, or even knocking it against a hard surface, can cause microscopic or visible chips that compromise performance. Always handle inserts carefully, preferably wearing gloves to protect both your hands and the sharp edges.

* Use Appropriate Protection: Always use sharp carbide insert blades. Dull blades require more force, generate more heat, and produce inferior results. Rotate inserts to fresh edges as soon as cutting performance diminishes (increased feed pressure, burning, poor finish). Don’t wait until they are completely blunt.

* Mind the Environment: Avoid exposing carbide insert blades to excessive moisture which can cause the steel body to rust, potentially affecting insert seating. Similarly, significant temperature fluctuations can potentially stress materials.

* Regular Inspection: Before and after use, visually inspect inserts for chips, cracks, excessive wear (flattening of the cutting edge), or signs of overheating (bluish discoloration). Inspect the blade body for damage to the seats, pockets, or clamping mechanisms. Check all fasteners for signs of stretching or damage .

* Lubrication (Where Applicable): While the inserts themselves don’t require lubrication, the moving parts of the cutter head assembly (e.g., on some shaper cutters or mechanical fastening systems) might. If specified by the manufacturer, use appropriate lubricants sparingly, ensuring they don’t attract excessive dust or contaminate wood surfaces.

By understanding the different types of carbide insert blades available, proactively addressing the common operational challenges with the solutions provided, and adhering rigorously to proper handling and maintenance routines, woodworkers can maximize the value, performance, and safety these advanced cutting tools offer. The initial investment in quality carbide insert blades pays dividends through superior results, reduced downtime, and lower long-term operational costs. Consistent care and attention to detail are the keys to unlocking their full potential.