In the world of wood joinery, the finger joint cutter stands as a specialized router bit designed to create incredibly strong and aesthetically pleasing interlocking joints. Also known as box joint cutters, these precision tools are fundamental for constructing durable corners in boxes, drawers, frames, and cabinetry. Understanding their function, overcoming common challenges, and adhering to safety practices are key to unlocking their full potential.

The Core Purpose: Strength and Efficiency

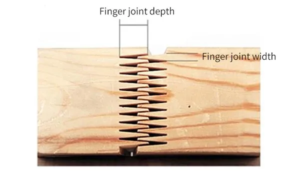

The primary role of a finger joint cutter is to machine perfectly matching “fingers” and “sockets” into the edges of two workpieces. When glued together, these meshing fingers create a large, long-grain gluing surface area. This significantly surpasses the strength of a simple butt joint and rivals or even exceeds the strength of many dovetail joints, especially when using modern adhesives. Beyond strength, finger joints offer:

* Decorative Appeal: They provide a distinctive, geometric look.

* Material Efficiency: They allow the joining of shorter boards into longer ones (finger-jointed lumber) with remarkable strength.

* Ease of Production (with Jigs): Paired with a well-made finger joint jig or a router table fence setup, they enable the rapid production of multiple identical joints.

Conquering Common Finger Joint Cutter Challenges: 4 Problems & Soluciones

Even with the right tool, issues can arise. Here are four frequent problems encountered with finger joint cutters and how to solve them:

- Problem: Rough or Torn Grain (Tearout)

Cause:

Cutting against the grain direction, dull cutter blades, or feeding the workpiece too fast, especially in brittle or figured woods.Solution:

Climb Cutting (Carefully!): For router table use, a very controlled climb cut (feeding opposite the normal direction) on the end grain side of the joint can yield a cleaner cut. This requires extreme caution due to increased risk of kickback; only experienced users should attempt it with firm workpiece control and minimal cut depth.

Sharp Blades: Ensure your finger joint cutter is razor-sharp. Dull blades crush rather than slice the wood fibers.

Slower Feed Rate: Reduce the speed at which you push the wood past the cutter.

Backer Board: Use a sacrificial backer board behind the workpiece to support the exit edge and prevent blowout.

Light Passes: Take multiple shallow passes instead of one deep cut. - Problem: Burn Marks on the Wood

Cause:

Excessive friction due to dull cutter blades, too slow feed rate, too high router speed, or cutting too deep in one pass, especially in hardwoods or dense materials.Solution:

Sharpen or Replace Blades: Dull blades generate heat through friction.

Increase Feed Rate: Move the workpiece steadily and consistently through the cut. Don’t linger.

Reduce Router Speed: Lower the RPM of your router. Refer to the finger joint cutter manufacturer’s recommendations for appropriate speeds based on bit diameter and wood density.

Take Lighter Passes: Reduce the depth of cut per pass. - Problem: Loose or Ill-Fitting Joints

Cause:

Incorrect setup is the usual culprit – the spacing between fingers/sockets doesn’t perfectly match the width of the cutter’s profile. This stems from inaccurate jig calibration, incorrect fence positioning on the router table, or inconsistent workpiece pressure during cutting.Solution:

Precise Jig Calibration: Meticulously set up your finger joint jig. Test cuts on scrap wood are essential before committing to your project wood. Measure the resulting finger/socket width accurately.

Router Table Fence Accuracy: Ensure the router table fence is perfectly perpendicular to the table and locked securely. Double-check the distance from the fence to the cutter’s cutting edge.

Consistent Pressure: Maintain firm and even pressure against the jig or fence throughout the entire cut. Any wobble or variation will affect fit.

Check Cutter Size: Ensure the width of the cutter’s profile matches the desired finger/socket size. Measure the actual cutting diameter. - Problem: Snipe (Deeper Cut at Start or End)

Cause:

The workpiece lifting slightly as it enters or exits the cut, often due to inadequate support before and after the cutter.Solution:

Featherboards: Use featherboards positioned before and after the finger joint cutter to hold the workpiece firmly down against the router table and in against the fence.

Outfeed Support: Ensure you have proper support extending past the cutter on the outfeed side to prevent the workpiece from tipping down as it exits the cut.

Push Blocks/Sticks: Use push blocks or sticks to maintain downward and forward pressure throughout the entire cut, especially over the start and end points. Never rely solely on hand pressure near the cutter.

Essential Precautions for Safe and Effective Use

Working with a finger joint cutter demands respect for safety and tool maintenance:

- Safety First:

Eye & Ear Protection: Always wear safety glasses and hearing protection.

Dust Collection: Use a dust mask or respirator and connect a dust collector. Routing creates fine, harmful dust.

Kickback Awareness: Be extremely vigilant about kickback, especially when climb cutting. Use sharp bits, secure workholding (featherboards, hold-downs), and maintain control. Keep hands away from the cutter’s path; use push blocks/sticks.

Secure Workpiece: Ensure the workpiece is firmly held against the jig or fence and cannot shift during the cut.

Router Stability: Ensure the router is securely mounted in the table and the table itself is stable.

- Tool Care & Setup:

Sharpness is Paramount: A sharp finger joint cutter is safer (requires less force, less prone to grabbing) and produces cleaner results. Inspect blades regularly and sharpen or replace as needed.

Correct RPM: Consult the manufacturer’s recommendations for router speed based on the cutter diameter and shank size. Larger diameters typically require lower RPMs.

Proper Installation: Ensure the cutter is fully seated in the router collet and tightened securely. A loose bit is extremely dangerous.

Appropriate Cut Depth: Never attempt to remove too much material in one pass. Take multiple shallow passes for cleaner cuts and reduced strain on the tool.

Clean the Bit: Pitch and resin buildup can cause burning and reduce cutting efficiency. Clean the finger joint cutter regularly with an appropriate bit cleaner.

Conclusion

The finger joint cutter is a versatile and powerful tool for creating exceptionally strong and attractive wood joints. By understanding its purpose, mastering the solutions to common problems like tearout, burning, poor fit, and snipe, and rigorously adhering to safety and maintenance precautions, woodworkers can consistently achieve professional results. Investing time in precise setup, using sharp tools, and practicing safe techniques will transform this specialized bit into a reliable cornerstone of your joinery repertoire. Remember, successful use of the finger joint cutter hinges on meticulous preparation and a deep respect for the tool’s capabilities.