In the world of woodworking, the right tools can transform your projects from ordinary to exceptional. One such game-changer is the helical spiral cutter head, known for its efficiency and smooth performance. Unlike traditional straight knife heads, a helical spiral cutter head reduces noise and provides cleaner cuts, making it a favorite among craftsmen.

This guide will delve into the essentials of using various cutter heads, highlight key precautions, and outline steps for upgrading to a helical spiral cutter head. Whether you’re a beginner or a seasoned woodworker, you’ll find practical advice to enhance your skills and safety.

Part 1: Usage Guidelines for Different Types of Cutter Heads

Understanding the different types of cutter heads is crucial for achieving optimal results in woodworking. Each type has its own strengths and applications, so let’s explore how to use them effectively.

第一的, consider the straight knife cutter head, which is an older design. It features simple, straight blades that are easy to install but tend to produce more noise and tear-out in wood. To use it, ensure the blades are sharp and securely fastened. Start by adjusting the depth of cut to avoid overloading the machine.

Always feed the wood steadily and avoid forcing it through, as this can cause kickback or uneven cuts. While this type is budget-friendly, many woodworkers recommend upgrading to a helical spiral cutter head for better performance. The helical spiral cutter head offers smoother operation and longer blade life, making it a worthwhile investment for those seeking improved finishes.

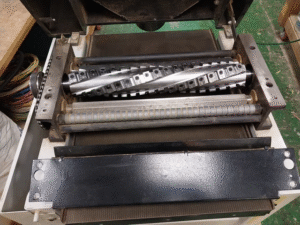

下一个, the helical light-cut cutter head is ideal for precision tasks and softer woods. It typically uses blades sized 15x15x2.5 mm or 14x14x2.0 mm, which are designed for gentle, efficient cutting. When using this helical spiral cutter head, begin by checking that the blades are properly aligned and not worn out.

Set your machine to a moderate speed to prevent burning the wood. Apply light pressure and make multiple passes if needed, rather than one deep cut. This approach minimizes stress on the blades and ensures a clean finish. The helical spiral cutter head in this configuration is perfect for detailed work, such as cabinetry or trim, where finesse is key.

For heavier tasks, like milling hardwoods or large-scale projects, the helical heavy-cut cutter head is your go-to option. It employs robust blades, often 30x12x1.5 mm, that can handle intense workloads. To use this helical spiral cutter head safely, start by verifying that your machine can support the increased load.

Adjust the feed rate to be slower than with lighter heads, allowing the blades to engage the wood thoroughly without stalling. Regularly inspect the blades for chips or dullness, as they work under high stress. This type of helical spiral cutter head excels in durability and is essential for professional workshops aiming for efficiency and longevity.

Part 2: Five General Precautions When Using Woodworking Cutter Heads

Safety and maintenance are paramount when working with cutter heads. Here are five essential precautions to keep in mind, regardless of the type you use.

- Prioritize Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and gloves when operating machinery. Cutter heads can generate flying debris and loud noise, especially with a helical spiral cutter head, which might run at high speeds. This basic step reduces the risk of injury and ensures a safer working environment.

- Inspect Blades and Components Regularly: Before each use, check for any signs of wear, such as nicks or corrosion. Dull blades not only produce poor results but also increase the chance of accidents. For a helical spiral cutter head, ensure the individual blades are tightly secured and replace them as needed to maintain peak performance.

- Follow Proper Installation Procedures: Incorrect installation can lead to machine failure or personal harm. Refer to the manufacturer’s guidelines when mounting or adjusting a cutter head. With a helical spiral cutter head, take extra care to align the blades correctly to avoid imbalances that could cause vibrations or breakage.

- Avoid Overloading the Machine: Pushing the cutter head beyond its capacity can damage both the tool and your workpiece. Start with lighter cuts and gradually increase the depth as you gauge the machine’s response. This is particularly important for a helical spiral cutter head, as overloading might lead to premature blade wear or motor strain.

- Maintain a Clean Workspace: Sawdust and debris can accumulate around the cutter head, posing fire hazards or interfering with operation. After each session, clean the area and the helical spiral cutter head itself to prevent buildup. Regular maintenance not only extends the tool’s life but also ensures consistent, high-quality cuts.

Part 3: Four Preparatory Steps Before Upgrading to a Helical Spiral Cutter Head

Upgrading from a straight knife head to a helical spiral cutter head can significantly enhance your woodworking experience, but it requires careful planning. Here are four key steps to prepare before making the purchase.

第一的, learn how to safely dismantle the existing cutter head. Begin by disconnecting the machine from power to prevent accidental startups. Use appropriate tools, like wrenches or screwdrivers, to loosen and remove the old head. Take notes or photos during disassembly to aid in reassembly later. This process might vary by machine model, so consult your manual if available. Proper dismantling ensures you don’t damage components and prepares the space for the new helical spiral cutter head.

Second, measure the critical dimensions of your current setup. Record the shaft diameter, 总体长度, and mounting hole positions. 还, note the machine’s horsepower and RPM ratings to ensure compatibility with a helical spiral cutter head. Accurate measurements help you select a replacement that fits perfectly, avoiding costly mistakes. If you’re unsure, consider seeking advice from a professional or referring to online resources tailored to helical spiral cutter head upgrades.

Third, assess your workshop’s requirements and the types of projects you handle. Determine if you need a light-cut or heavy-cut helical spiral cutter head based on your typical materials and workloads. For instance, if you often work with hardwoods, a heavy-duty option might be best. This evaluation ensures that the new helical spiral cutter head aligns with your needs, maximizing its benefits and efficiency.

Fourth, gather all necessary tools and resources for the installation. This includes replacement blades, lubrication, and any specialized equipment mentioned in the upgrade guidelines. Having everything on hand streamlines the process and reduces downtime. Remember, a helical spiral cutter head upgrade is an investment in quality, so thorough preparation pays off in smoother operations and better results.

In conclusion, mastering the use of cutter heads, particularly the helical spiral cutter head, can elevate your woodworking projects to new heights. By understanding the different types, adhering to safety precautions, and preparing adequately for upgrades, you’ll enjoy quieter, cleaner cuts and extended tool life. Embrace these tips to make the most of your helical spiral cutter head and transform your workshop into a hub of precision and creativity.