Wenn Sie sich für Holzbearbeitungswerkzeuge entscheiden, Der Verkäufer fragt Sie möglicherweise, ob Sie Wolframkarbid oder Schnellarbeitsstahl benötigen. Wie sollten Sie zu diesem Zeitpunkt wählen?, und was sind die Unterschiede zwischen ihnen. Nachdem ich diesen Artikel gelesen habe, wenn Sie sich erneut für Ihre Holzbearbeitungswerkzeuge entscheiden, you may have a clearer understanding of the choice of these two materials.

Erstens, what is high speed steel and what is tungsten steel?

HIGH SPEED STEEL

Hochgeschwindigkeitsstahl (HSS) is a tool steel with high hardness, high wear resistance, and high heat resistance. It is also called wind steel or edge steel, which means it can harden and be sharp even when cooled. Air during quenching. Some are called white steel.

High-speed steel is an alloy steel with complex composition, containing carbide-forming elements such as tungsten, molybdenum, chromium, vanadium, and cobalt. The total amount of alloying elements is approximately 10-25%. High-speed steel cutting tools can be divided into tungsten series and tungsten-molybdenum series steel according to their chemical composition. They can be divided into ordinary high-speed steel and high-performance high-speed steel according to their cutting performance.

When high-speed steel is quenched, the iron, chromium, part of tungsten and carbon in the high-speed steel form extremely hard carbides, which can improve the wear resistance of the steel and make its hardness reach HRC64-68. Another part of tungsten is dissolved in the matrix, increasing the red hardness of the steel. The red hardness of high-speed steel can reach 650 Grad.

High-speed steel is mainly used to manufacture complex thin-edged, impact-resistant metal cutting tools as well as high-temperature bearings and cold extrusion molds, such as turning tools, end mills, hobs, machine saw blades and molds. High demands.

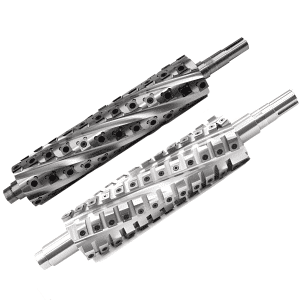

TUNGSTEN CARBIDE

The main components of tungsten steel are tungsten carbide and cobalt, accounting for 99% of all components, and other metals accounting for 1%. Deshalb, it is called tungsten steel, also known as cemented carbide.

Tungsten steel (tungsten carbide or tungsten carbide) has a series of excellent properties such as high hardness, Verschleißfestigkeit, good strength and toughness, heat resistance, and corrosion resistance. Insbesondere, its high hardness and wear resistance remain basically unchanged even at 500°C, and its hardness is very high at 1000°C.

Tungsten steel is a sintered composite material composed of at least one metal carbide. It uses cobalt, molybdenum and nickel as binders and is sintered under high temperature and high pressure. Its hardness is as high as HRC75-80. Gleichzeitig, the red hardness of cemented carbide can reach 800-1000 Grad.

Zweitens, we will briefly analyze the advantages and disadvantages of high-speed steel cutting tools and tungsten steel cutting tools:

HIGH SPEED STEEL CUTTING TOOLS

Vorteile: low price, high strength, good toughness, and high degree of standardization.

Disadvantages: poor wear resistance, low hardness, not resistant to high temperatures, low cutting efficiency, and processing dimensions are easily affected by temperature.

TUNGSTEN CARBIDE CUTTING TOOLS

Vorteile: high cutting efficiency, hohe Härte, Verschleißfestigkeit, hohe Temperaturbeständigkeit, stable processing quality, good precision processing effect, stable processing size, not easily affected by temperature, often used in the field of precision processing.

Disadvantages: low bending strength, poor impact toughness, high brittleness, low ability to withstand shock and vibration, and high price.

Many customers order high-speed steel molds or blades to save purchasing costs; but in the processing of metal and wood products, carbide cutting tools are still more competitive and cost-effective.

If you are looking for the right woodworking tools or metalworking tools for your project, please click on our store homepage to view our products. If you are interested in any products, Sie können uns gerne kontaktieren, we have been in the cutting tools industry for more than 24 Jahre, with rich experience and competitive prices.

1 1/4″ X1″ Pechholz 1075 Klinge aus Kohlenstoffstahl, 10-Zoll-Säge 13 Zoll Tct Bandsägeblätter