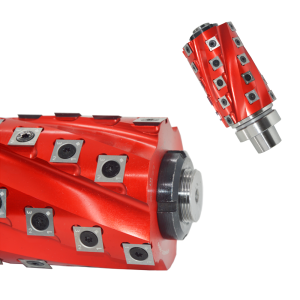

Product Introduction

|

|

Material

|

Working Diameter(mm)

|

Wing(T)

|

|

Light Duty Helical Spiral Cutter Head

|

Steel

|

45-55

|

3/4/5

|

|

45-55

|

4/5/6

|

||

|

80-100

|

6

|

||

|

110-125

|

6-8

|

||

|

Heavy Duty Helical Spiral Cutter Head

|

Steel

|

55-72

|

3/4

|

|

75-90

|

4-6

|

||

|

100

|

6

|

||

|

125

|

6

|

||

|

Other specifications can be customized

|

Possible Problems & Solutions

PROBLEM: Planed boards have uneven patches

REASON①: The machine speed is not enough

For a helical spiral cutter head with a diameter of 75-125mm, the machine speed needs to be 5,000-12,000 rpm;

The larger the diameter of the helical spiral cutter head, the smaller the machine speed required;

In addition, the spindle speed of the helical spiral cutter head using tungsten carbide inserts would more higher than that of high speed steel inserts.

The larger the diameter of the helical spiral cutter head, the smaller the machine speed required;

In addition, the spindle speed of the helical spiral cutter head using tungsten carbide inserts would more higher than that of high speed steel inserts.

SOLUTION①: Use a traditional cutter head with insert straight high speed steel planer blades instead of a helical spiral cutter head with insert carbide blades

PROBLEM: Planed boards have striped unevennessREASON①: There is chipping of the insert blade in the circumferential area of the cutter.SOLUTION①: Replace the broken insert blades.REASON②: There is a drop in the insert blade in the annular part of the cutter.SOLUTION②: First check whether there is a loose blade in the annular part of the cutter; if there is no loose blade, it meansthere is a drop in the blade; We need to remove all the blades in the ring part first and clean the wood ash on these blades;After cleaning, change the cutting edge of the insert blades and reinstall it.

Packaging & Shipping

Company Introduction

Why Choose Us

Contact Information

|

Contact Person

|

Emma

|

|

WhatsApp/ Phone Number

|

+86 13825289615

|

|

WeChat

|

DHcutter

|

|

E-mail Account

|

Emma@dhcutter.com

|

Related Products

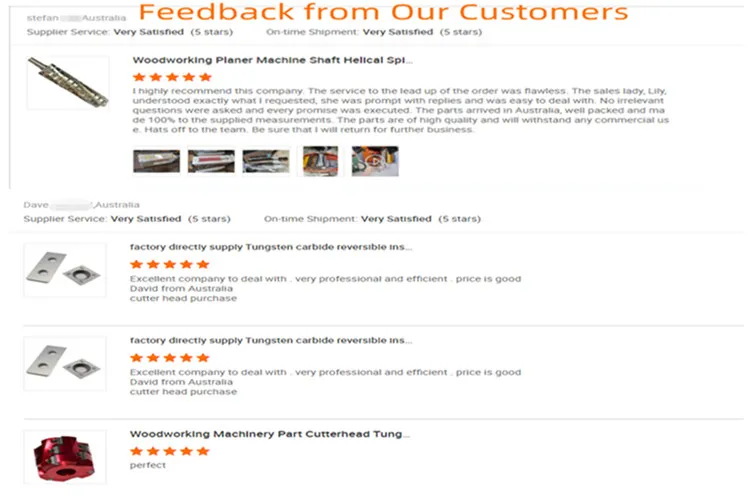

Reviews

There are no reviews yet.