In daily work, there are several reasons why we may need to replace circular saw blades:

First, the blade may be damaged or dull. This is a must-replace saw blade. Continuous use of dull or broken saw will not only fail to cut the ideal plane, but may also cause safety hazards.

Or we may need to cut some metal, but our circular saw is equipped with a wood cutting blade, which means a change in cutting materials. Different circular saw for different cutting materials are completely different, so it is very important to follow up on different cutting materials to replace saw blades.

Whatever the reason, when we need to replace saw, what preparations do we need to make and what details do we need to pay attention to? This article will tell you one by one.

·Saw Blade Size

When replacing saw blades, the first important thing we need to know is: what size saw do I need?

Usually when you buy a circular saw, its specific size will be printed on the box and the saw blade itself. You can easily know what size you need through the specifications on the box and the saw blade.

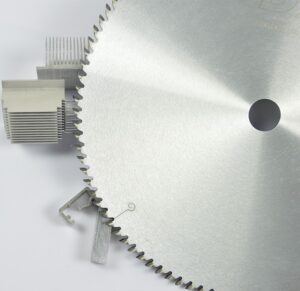

If the box has been lost or the dimensions on the saw blade have worn off unfortunately, then we need to measure the saw blade to find out the specific dimensions. The data we need to measure are the diameter of the saw, the diameter of the arbor, and the number of teeth of the circular saw blade.

First, we remove the circular saw that needs to be replaced from the saw. The diameter is the measurement from the center of the blade to the other side, and we will use this measurement to purchase a saw that fits the size of the circular saw.

At the same time, the hole diameter in the center of the saw blade also needs to fit the shaft or arbor of the circular saw, that is, we also need to measure the diameter of the arbor hole.

For the number of teeth of the circular saw blade, it depends on the type of material we need to cut. If the cutting material has changed, it is necessary to choose a new and appropriate number of teeth when replacing the saw. Of course, if the saw blade is replaced because the saw is damaged or dull, keep the same number of teeth as the circular saw.

Generally, saw blades with more teeth cut slower, but the cut edges are smoother and edge chipping is less likely to occur. Saw blades with fewer teeth cut faster and usually produce rough, choppy cuts, making them more suitable for roughing or cutting projects that do not require a high surface finish.

· Types of Saw Blades

The type of saw blade you choose depends on the material you are cutting. Wood is the material we most often cut with a saw, and the most common types of cuts we make are longitudinal and transverse cuts.

For different types of cuts, there are different types of saw blades. When changing saw, we need to know exactly what type of saw we need: longitudinal blades have fewer teeth. Usually less than 40. When we look down at the teeth of longitudinal blades, we notice that the top of the teeth is flat. Whereas transverse blades have more teeth. Usually more than 40. When we look at the teeth of transverse blades, we notice that the top of the teeth are “V” shaped or form a valley in the center of the blade.

Of course, there are also combination saw, which can cut both longitudinally and transversely.

At the same time, the saw used to cut metal, plastic, and concrete are also different. When changing blades, you need to know the type of blade you need to replace in order to perfectly complete the smooth replacement of the blade.

·Direction of the Saw Blade

This is a point that is very easy to overlook during the replacement process: the direction of the saw blade.

Almost all circular saw have an arrow that is printed or engraved on the saw body. This arrow indicates in which direction the saw should be installed on the saw. The arrow needs to point to the front of the circular saw. If we do not see an arrow, the teeth need to face the front of the saw.

·Other Precautions

1-Be sure to tighten the circular saw after replacing it;

Most screws are right-hand threads. This means that the screw can be loosened by turning it to the left and tightened by turning it to the right. You can simply remember it as “tighten on the right and loose on the left”.

If the circular saw uses a left-hand thread screw to fix the blade. This is the opposite of “tighten on the right and loose on the left”. This means that the circular saw screw must be turned to the right to loosen it and turned to the left to tighten it.

2-Disconnect the power supply of the machine when changing the circular saw;

Unplug the circular saw from the socket or remove the battery from the saw. This is very, very important and is related to the safety of the operator, so please remember it.

Hope the above tips will be helpful to you who need to replace circular saw. You are also welcome to share your own problems or experiences when replacing saw in the comment section, and we can discuss them together.