The table saw is one of the most versatile and widely used tools in woodworking, capable of performing a variety of tasks with precision and efficiency. From ripping lumber to crosscutting panels, the table saw is indispensable in both professional workshops and home garages. However, when it comes to cutting laminated panels, such as veneered plywood or melamine-coated boards, achieving a clean, chip-free edge can be challenging. This is where the importance of a table saw equipped with a scoring device becomes evident. In this article, we will delve into the definition, functionality, and applications of scoring blades, as well as their role in enhancing the quality of woodworking projects.

The Challenge of Cutting Laminated Panels

If you have ever attempted to cut plywood or other laminated materials on a table saw, you may have encountered issues such as chipping, splintering, or uneven edges. These problems are particularly common when cutting materials with delicate surfaces, such as veneers or laminates. The primary cause of these issues is the way the saw blade interacts with the material. As the blade cuts through the workpiece, the upward rotation of the teeth can cause the fibers on the bottom surface to tear out, resulting in a rough and unsightly edge.

This is where the advantages of a sliding table saw come into play. A sliding table saw allows you to secure the material to a sliding carriage, which can be smoothly pushed through the blade. This setup not only ensures a consistent feed rate but also reduces the likelihood of chipping. However, even with a sliding table saw, achieving a perfectly clean cut on laminated materials can be difficult without the use of a scoring blade.

What is a Scoring Blade?

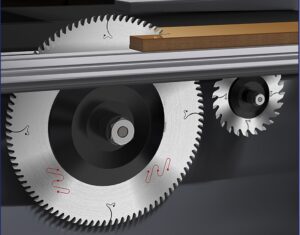

A scoring blade is a small, specialized blade that is mounted in front of the main saw blade on a table saw. Its primary purpose is to make a shallow, preliminary cut on the bottom surface of the workpiece before the main blade makes the full cut. This shallow cut, or “score,” helps to prevent chipping and splintering by severing the fibers on the bottom surface of the material before the main blade passes through. As a result, the main blade can make a clean, precise cut without causing tear-out.

The scoring blade is typically 0.1 to 0.2 millimeters wider than the main blade, ensuring that it cuts slightly wider than the main blade to prevent binding. It is installed with its teeth facing backward and rotates in the opposite direction to the main blade. This reverse rotation ensures that the scoring blade cuts cleanly into the bottom surface of the material, while the main blade completes the cut from above. The scoring blade is set very low, just deep enough to score the surface of the material, and its shallow cut depth ensures that the material’s weight prevents it from being dragged forward.

Types of Scoring Blades

There are two main types of scoring blades: adjustable scoring blade sets and tapered scoring blades.

1. Adjustable Scoring Blade Sets: These sets consist of two carbide-tipped blades and a spacer. The spacer is used to adjust the cutting width, allowing you to fine-tune the scoring blade to match the thickness of the material being cut. This type of scoring blade is ideal for applications where precision is critical, such as cutting laminated panels or veneered plywood.

2. Tapered Scoring Blades: Tapered scoring blades consist of a single blade with a unique tooth geometry known as ATB (Alternate Top Bevel). This tooth design, combined with a positive cutting angle, ensures sharp, smooth cuts and prevents chipping on the bottom edge of the material. The cutting width of a tapered scoring blade can be adjusted by changing its height, making it a versatile option for a variety of materials.

Applications of Scoring Blades

Scoring blades are particularly useful when cutting materials that are prone to chipping or cracking, such as MDF (medium-density fiberboard), laminate, hardboard, multi-layer boards, and fire-resistant materials. These materials are commonly used in furniture making, cabinetry, and interior design, where the quality of the cut is of utmost importance. By using a scoring blade, woodworkers can achieve clean, chip-free edges that require minimal sanding or finishing, saving time and effort in the workshop.

Choosing the Right Scoring Blade

When selecting a scoring blade, it is important to consider the type of material you will be cutting, as well as the specific requirements of your project. For example, if you frequently work with laminated panels, an adjustable scoring blade set may be the best option, as it allows for precise adjustments to the cutting width. On the other hand, if you need a versatile blade that can handle a variety of materials, a tapered scoring blade with ATB tooth geometry may be more suitable.

It is also important to ensure that your table saw is equipped with a scoring device before using a scoring blade. Not all table saws come with this feature, so it is essential to check your saw’s specifications before making a purchase.

Conclusion

In conclusion, scoring blades are an invaluable tool for woodworkers who need to achieve clean, precise cuts on laminated materials. By making a shallow, preliminary cut on the bottom surface of the workpiece, scoring blades prevent chipping and splintering, resulting in a smoother, more professional finish. Whether you are working with veneered plywood, MDF, or laminate, a high-quality scoring blade can make all the difference in the quality of your work.

As an experienced supplier of scoring blades, DH is committed to providing woodworkers with the tools they need to achieve exceptional results. Our industrial-grade scoring blades are designed to deliver sharp, smooth cuts on a wide range of materials, from MDF to fire-resistant boards. If you are looking for high-performance scoring blades for your business or workshop, we invite you to contact us. Our sales team is ready to offer professional support and help you find the perfect scoring blade for your needs. With the right tools and techniques, you can take your woodworking projects to the next level.