With the development of science and technology, cutter heads have gradually replaced traditional flat knives and four-sided planers. At present, spiral cutterheads have become standard tools for woodworking machinery in Europe and the United States.

Why do more and more people or factories choose to use spiral cutter heads for wood cutting or processing? The traditional flat cutterhead mainly depends on the sharpness of the flat knife, while the spiral cutterhead more scientifically distributes the planing points evenly to each blade, while fine-tuning the blade and the processing surface angle. By doing so, the spiral cutter head can be easily adjusted to adapt to the processing of different materials.

As the spiral cutterhead has become a dark horse in the woodworking machinery market, many people still know little about the spiral cutterhead. This article will briefly talk about this new favorite in the woodworking industry, hoping to help everyone understand this popular wood work tool.

First of all, we need to know the classification of cutter heads: there are three types of tungsten steel cutter heads for woodworking, namely light-duty cutterhead, heavy-duty cutterhead, and high-feed cutterhead.

Light-duty Cutter Head

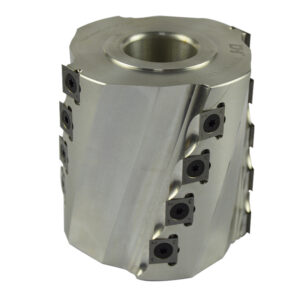

The structure of the light-duty cutterhead includes a spiral cutter body, a spiral groove, a reversible knife, a countersunk screw, etc. Mainly used for vertical axis machines, four-sided planers, etc., the main cutting surface is smooth and round.

The spiral cutter body is the basis of the light cutting spiral cutterhead, ensuring that the tool still has good mechanical strength under high-speed rotation. When the tool is continuously cutting, a large amount of sawdust will be formed, which can be discharged in time through the chip groove to improve the heat dissipation performance and processing quality of the tool. The woodworking reversible blade is fastened with a countersunk screw to ensure that the blade does not deflect or fall off during processing.

Heavy-duty Cutter Head

The heavy-cutting spiral cutterhead consists of a spiral cutter body, a spiral groove, a pressure block, a stud, and a discarded blade. It is mainly used for automatic profiling milling machines, vertical axis machines, four-sided planers, cutting shaping, etc.

Compared with the light cutting spiral cutterhead, the heavy cutting spiral cutterhead uses a pressure block and a stud to lock the discarded blade, making the blade clamping more stable and the tool can carry a coarser cutting amount. But both can be used on almost the same materials and can be installed on the four-sided planer.

High-feed Cutter Head

The structure of the high-feed cutterhead includes a spiral cutter body, spiral groove, reversible cutter, screw for hole, etc. The overall components of the high-feed spiral cutter head are very similar to those of the light-cut spiral cutter shaft, but its appearance and cutting performance are still somewhat different from those of the light-cut cutter.

The spiral groove of the high-feed spiral cutter head is deeper, the wood rotation is less resistant, and its chip removal ability and heat dissipation performance are also stronger. It is mainly used for solid wood, veneer and plastic processing.

The spiral cutterhead scientifically distributes the planing points evenly on each processing blade, and finely adjusts the angle between the blade and the working surface, which can be easily adjusted to adapt to different materials.

At the same time, according to different materials and different dryness and humidity, woodworkers can replace different carbide blades; if one edge of the blade is blunt or notched, just loosen the screw to turn to another edge and lock the blade without grinding. Only when all four edges of a knife cannot be used, a new blade needs to be replaced.

The service life of the spiral blade is 5 to 12 times that of ordinary blades, which not only saves the time of sharpening and proofreading, but also improves the planing efficiency, reduces the cost of use, reduces power consumption, and overcomes the problems of scabbing and cracking, uneven reverse grain, surface warping and depression when planing wood boards with traditional blades. Especially on hardwood, bamboo, bamboo board, plastic board, insulation board and other materials that are not easy to process, it has more advantages and production capacity.

Spiral cutter heads are DH’s hot-selling products. Common light spiral cutter heads, heavy spiral cutter heads and high-feed spiral cutter heads can be provided, which can be specially used for wood mills with large planing volume or fine processing requirements; at the same time, other types of non-standard cutter heads also support customized services. Of course, if you just need to replace the carbide blade for your cutter head, we can also serve you one-stop.

https:/shop/planer-replacement-helical-cutter-head-wood-shaper-moulder-spindle-spiral-cutter-7/