The multi-spindle drill is a powerhouse for efficient woodworking, but its performance and the quality of your work are profoundly influenced by the condition and choice of your drill bits. Neglecting this crucial component can lead to a range of frustrating issues that compromise precision and productivity. By mastering common troubleshooting techniques, implementing a consistent maintenance routine, and selecting the right tools for the job, you can transform this machine into a reliable asset that consistently delivers flawless results.

Common Problems and Practical Solutions

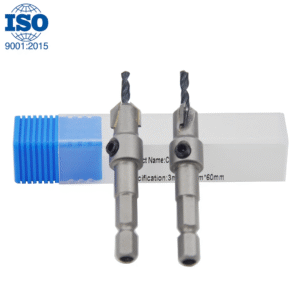

One of the most frequent issues encountered is tear-out or splintering around the hole edges. This is often a direct result of using dull or inappropriate drill bits. A bit that has lost its sharpness doesn’t cut cleanly; it tears and crushes the wood fibers. The solution is twofold. First, regularly inspect and sharpen your drill bits,or replace them when they become excessively worn. Second, match the bit to the material. For delicate veneers or laminated surfaces, using brad-point or Forstner drill bits can provide a much cleaner entry and exit hole due to their sharper definition and shearing action.

Another common headache is misaligned or inaccurately spaced holes. This can stem from several causes. If the machine itself is out of alignment, the problem will be consistent. Check the alignment of the spindles and the fence, making adjustments as per the manufacturer’s instructions. However, the issue might also be with the workpiece or the setup. Ensure the wood is held firmly against the fence and the table is clean of debris. For complex patterns, using a well-made template can eliminate positioning errors. Sometimes, the problem is not the machine but the drill bits wobbling in a worn-out collet. Inspecting and replacing worn collets is crucial for maintaining precision.

Breakage of the drill bits themselves is a frustrating and costly problem. This is frequently caused by applying too much feed pressure, especially when using smaller diameter drill bits. Let the tool do the work; forcing it through the wood creates excessive heat and stress, leading to snapage. Ensure you are using a sharp set of drill bits, as dull ones require more pressure to cut. Furthermore, a lack of clearing of wood chips from the holes can cause bits to bind and break. When drilling deep holes, use a pecking motion—drill a short distance, retract to clear chips, and then continue—to keep the flutes clean.

Excessive noise and vibration are signs that something is amiss. This could indicate that the drill bits are unbalanced, damaged, or incorrectly installed. Always ensure each bit is securely tightened in its collet. Vibration can also be caused by a loose drive belt or issues with the motor bearings, which require mechanical inspection. Sometimes, the simple act of ensuring you are using a matched set of high-quality drill bits can dramatically reduce vibration and ensure smoother operation.

The Importance of Regular Maintenance

Proper is not just about fixing problems; it’s about preventing them. A well-maintained multi-spindle drill is a safe and accurate machine. After each use, make it a habit to clean the entire machine. Blow away or vacuum all wood dust and chips from the table, fence, and spindles. Dust buildup can interfere with moving parts and accuracy.

Lubrication is the lifeblood of the machine. Follow the manufacturer’s guidelines to regularly lubricate all moving parts, such as the spindle bearings and the adjustment mechanisms. This prevents wear and ensures smooth operation. The drill bits themselves are a critical component of maintenance. Store them in an organized case to prevent them from knocking against each other and becoming dull. A periodic sharpening regimen for your drill bits is one of the best investments you can make in the quality of your work.

Selecting the Right Drill Bits for the Job

Choosing the right multi-spindle drill involves considering your specific needs. For a small shop focused on custom furniture, a manually adjusted machine with a handful of spindles might be sufficient. For a production environment, a machine with a pneumatic clamping system and automatic feed would be necessary for speed and consistency.

The material you work with most often should guide your choice of drill bits. For general softwood and hardwood, high-speed steel (HSS) drill bits are adequate. However, for abrasive materials like MDF or laminates, carbide-tipped drill bits will maintain their sharpness far longer. The design of the drill bits also matters; bits with a positive rake angle cut more aggressively and cleanly in wood.

In conclusion, the multi-spindle drill is a powerful ally in the workshop. By understanding how to troubleshoot common issues like tear-out and breakage, implementing a rigorous cleaning and lubrication schedule, and selecting the right machine and sharp drill bits for your materials, you can harness its full potential. This proactive approach will lead to cleaner results, a safer working environment, and a tool that serves you well for years to come.