In the world of woodworking, frame saw blades play a crucial role in achieving clean and accurate cuts. These blades, mounted on a saw frame, are designed for various tasks such as rip cutting, crosscutting, and intricate joinery work. Their ability to handle different wood types and thicknesses makes them indispensable for both beginners and seasoned craftsmen.

However, like any tool, frame saw blades can encounter issues that hinder performance. This article will explore the main functions of frame saw blades, discuss five common problems with practical solutions, and offer essential safety advice to ensure optimal and secure use in your projects.

Frame saw blades are primarily used for cutting wood along or across the grain. They consist of a thin, flexible blade held taut in a frame, which allows for controlled and precise movements.

In woodworking, these blades excel at tasks like tenoning, dovetailing, and general shaping, thanks to their versatility. The tension in the frame keeps the blade straight during cuts, minimizing deflection and ensuring smoother operations.

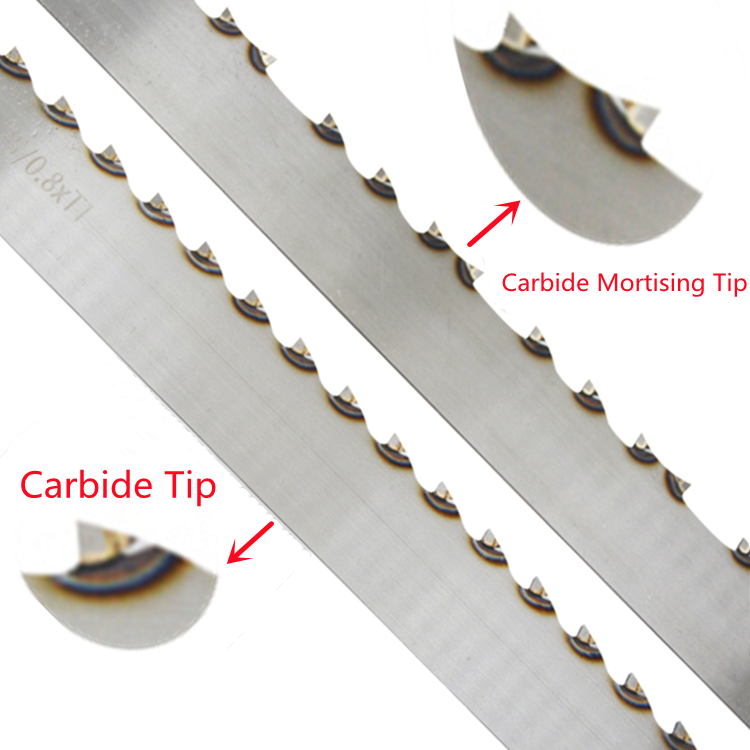

Moreover, frame saw blades come in various tooth configurations, enabling users to select the right blade for specific materials, from softwoods to hardwoods. Their adaptability extends to curved cuts when paired with narrower blades, making them a staple in traditional and modern workshops alike. Understanding these functions helps users appreciate why maintaining frame saw blades is key to woodworking success.

Despite their utility, frame saw blades can develop problems that affect performance. Here are five common issues and how to address them:

Frame Saw Blades Bending or Warping

Bending or warping is a frequent issue with frame saw blades, often caused by improper tension or storage. When the blade isn’t adequately tightened, it may flex during cuts, leading to inaccuracies.

To solve this, always check the tension before use—ensure the blade is securely fastened and adjusted per manufacturer guidelines. Store frame saw in a dry, flat place to prevent deformation from moisture or pressure. Regular inspections for wear can also avert bending, prolonging the life of your frame saw blades.

Cutting Off-Line or Wandering

If a frame saw blade cuts off the intended line, it results in uneven or misaligned work. This typically occurs due to a dull blade or misaligned saw frame.

To fix this, sharpen or replace the blade if it shows dullness. Ensure the saw frame is held steady and perpendicular to the workpiece. Using a guide or marking knife to score the cut line can improve accuracy. Consistent strokes and proper posture further help in achieving straighter cuts with frame saw blades.

Blade Binding or Sticking

Binding or sticking during cuts makes sawing difficult and is usually due to excessive friction or kerf pinching.

To mitigate this, apply a lubricant like wax or soap to the blade to reduce friction. Ensure the cut is wide enough to prevent the wood from closing in on the blade. If binding persists, check the blade’s tooth set—the alternating bend of teeth—and adjust if needed. Proper technique, such as a rocking motion at the start of cuts, can prevent binding in frame saw blades.

Rapid Blade Wear

Frame saw may wear out quickly if used incorrectly or on unsuitable materials. Factors like cutting too fast, using the wrong tooth count, or working with abrasive woods accelerate wear.

To extend blade life, match the frame saw blades to the task—for example, use fine-toothed blades for hardwoods and coarse-toothed ones for softwoods. Avoid forcing the saw; let the blade work at a steady pace. Regular cleaning and occasional sharpening keep frame saw blades in top condition, reducing replacement frequency.

Excessive Noise or Vibration

Unusual noise or vibration while using frame saw often indicates loose components, an unbalanced blade, or misalignment.

To resolve this, tighten all nuts and bolts on the saw frame for stability. Inspect the blade for damage or uneven teeth that might cause vibration. If issues continue, consider replacing the blade with a higher-quality option. Maintaining a well-tuned saw frame and blade reduces noise and enhances the cutting experience with frame saw blades.

In addition to troubleshooting, safety is paramount when working with frame saw blades.

—Always wear safety goggles to shield your eyes from wood chips and debris.

—Keep your work area clean and well-lit to prevent accidents.

—When handling blades, ensure your hands are away from the cutting path, and use a push stick for small pieces.

—Secure the workpiece firmly with clamps to avoid slipping.

—Regularly inspect frame saw blades for cracks or defects that could lead to breakage.

By following these tips, you minimize risks and foster a safe woodworking environment.

In summary, frame saw blades are versatile tools that, with proper care, deliver excellent results in woodworking. Addressing common problems like bending, off-line cuts, binding, wear, and vibration enhances efficiency and precision.

Prioritize safety to prevent injuries, and with the right techniques, frame saw blades will remain reliable companions in your workshop for years to come.