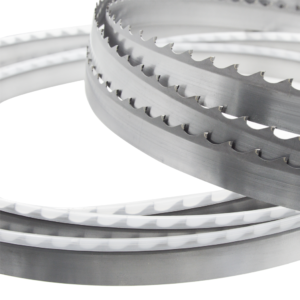

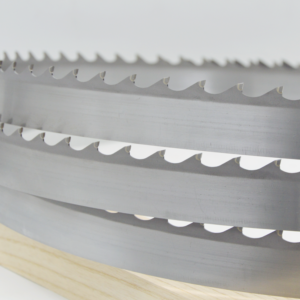

Bandsaw blades tension is the term used to describe how tight a band saw blade is on a band saw, expressed in pounds per square inch (PSI). To consistently produce straight, even cuts, band saw blades require tension.

Whether you are a professional woodworker, metal fabricator, or a hobbyist who appreciates the importance of precision in your creations, understanding how to properly tension a band saw blade is essential. Properly set tension improves your band saw’s cutting accuracy, extends the life of your blade, and supports efficient band saw operation.

In this article, we’ll take a brief look at the relationship between bandsaw blades tension and blade performance and life, learn techniques for setting proper tension, and more.

How Bandsaw Blades Tension Affects Performance and Life

Every bandsaw blade for a specific job requires its own form of tensioning.

The relationship between bandsaw blades tension and its performance and life is complex and critical: too much or too little tension can lead to a variety of problems that compromise the tool’s efficiency and the life of the blade.

Insufficient Tension

Insufficient tension can cause the bandsaw blades to shift or drift during the cut, resulting in inaccurate and inconsistent cuts. This results in more scrap during the cutting process and longer cutting times due to the need for corrections.

At the same time, an under-tensioned blade may slip on the bandsaw wheel. This slippage causes uneven wear on the blade’s trailing edge, leading to premature blade failure and the need for frequent blade replacement, which leads to increased operating costs.

Excessive Tension

Excessive tension puts unnecessary stress on the blade, making it brittle, causing cracks, fractures, and premature blade failure, while significantly increasing the risk of blade breakage. Blade breakage not only stops your work, but also poses a serious safety hazard, posing a risk to the operator and anyone else near the machine.

In addition, excessive pressure on the wheel bearings, motor, and frame of the bandsaw can cause premature wear and potential damage to the machine, resulting in expensive repairs and downtime.

So in order to achieve the best performance from the bandsaw machine and the bandsaw blades used, the right tension is essential. So how should we find the best tension for the bandsaw blades?

How to adjust according to the factors affecting tension

Most bandsaw machines are equipped with a built-in tensioning scale or indicator. They are very useful for setting the initial tension or relatively changing the tension. It’s important to note, however, that these indicators aren’t always 100% accurate – they should be used as a guide rather than an absolute measurement.

When setting the tension on your bandsaw blades, it’s important to note that the correct tension is not a static number, but varies based on several factors. The following key considerations will help you understand how to adjust the tension to suit your specific situation:

Blade Size

The width, thickness, and length of a bandsaw blade all affect its tension requirements. Wider and thicker blades generally require more tension than narrower and thinner blades.

As for length, longer blades may require slightly higher tension because there is more stretch over a larger area.

Cutting Materials

Harder materials require the blade to maintain a straight and steady path under high pressure, so higher tension is required.

Softer materials, on the other hand, don’t put as much pressure on the blade, so lower tension levels may be sufficient. At the same time, the high tension requirements of hard materials need to be balanced against the potential for blade stress and wear.

Remember that tensioning is not a set-it-and-forget-it operation. Bandsaw blade tension needs to be checked and adjusted regularly to account for factors such as blade wear, changes in the material being cut, or changes in environmental conditions such as temperature.

Regular inspection and adjustment helps ensure your band saw blade is always operating at optimal tension, which improves performance, increases cut quality, and extends blade life.