Insert carbide blade is essential tool in the woodworking cutting process, playing a crucial role in achieving accurate, smooth, and clean surfaces on workpieces. High-quality carbide blade knives are widely used for direct contact with the workpiece surface.

Carbide insert blade of various shapes play a crucial role in skilled applications. They are typically categorized into three types based on their specific usage: flat scrapers, triangular scrapers, and crescent scrapers. This article will briefly explore the different application scenarios for these blades.

Before delving into the application scenarios, it is essential to grasp the fundamental types of blades.

Flat insert carbide blade are the most commonly utilized type and are primarily employed for scraping flat surfaces such as planes, flat rails, workbenches, and similar surfaces. They can also be used for scraping outer surfaces.

Triangular insert carbide blades are a type of tool used for scraping bearings, characterized by their fracture in the shape of an equilateral triangle. To facilitate sharpening, arc grooves are opened in the middle of each surface to reduce the grinding area. However, once the triangular scraper begins working, it is difficult to change direction and may leave some vibration marks after processing. Therefore, triangular scrapers are typically used in conjunction with crescent scrapers.

Crescent insert carbide blades are primarily utilized for the purpose of scraping inner surfaces, such as the inner bore of a movable bearing. These scrapers are commonly employed as rollers and exert a straight-line forward force on the surface, making them effective in eliminating chatter marks.

Carbide blades are multifunctional and suitable for a wide range of applications, including joining, profiling, wood turning, milling, and scraping.

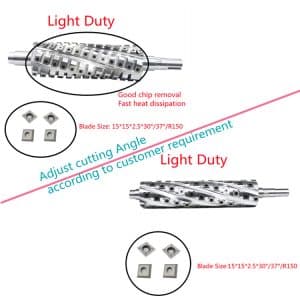

CUTTER HEAD

Flip carbide blade can be mounted on the blade heads of various machines, such as jointers, planers, mold machines, edge banding machines, etc. These blades are made of solid tungsten carbide, which has good wear resistance and high temperature resistance, and have excellent cutting performance and extended service life.

In addition, when one cutting edge is dull or damaged, you can turn it into a new edge. Carbide blades come in a variety of sizes and shapes, especially for mold machines. Strictly speaking, the knives mounted on the forming blade heads are usually called forming knives. Unlike forming knives, the blades used in the blade heads of jointers and planers are mostly square or rectangular. 15mm*15mm*2.5mm is one of the most commonly used sizes.

WOODTURNING INSERT

Woodworking turning blades are also made of solid carbide. Woodworking turning inserts basically come in three shapes: square, round, and diamond.

CNC INSERT ROUTER BIT

Unlike conventional router bits that have carbide inserts welded to the head, CNC plunge router bits come with carbide inserts. When the inserts are dull, we can replace them with new ones without having to throw away the drill bit. Similar to profile cutters, these inserts come in a variety of shapes and sizes for different contouring purposes.

CARBIDE SCRAPERS

Just like woodworking turning tools, carbide scrapers are also hand tools. They are mainly used to remove paint, rust, glue, varnish, etc. Usually, carbide scrapers come in four shapes: square, rectangular, triangular, teardrop, and pear.

Insert carbide blades are the main tool used in scraping. Scrapers’ materials and types will make a difference in their work efficiency. Hope this article made you know more things about woodworking.

DH focuses on B2B sales of woodworking tools, and carbide insert cutters are one of our main products. Our products are manufactured with a complete CNC production line. From WC powder selection to quality inspection, every step is strictly controlled by our engineers. We can guarantee that our customers will be happy that they have received value for money investment. We are looking forward to partners from all over the world.