End mills and router bits are commonly used tools in CNC machine tools. Both have spiral grooves and look similar. But they vary widely in structure, purpose and price. However, what’s the difference? Here is an article detailing them for your reference.

Definition: End Mills vs. Router Bits

First, what is an end mill?

End mills are commonly used in the woodworking and metalworking industries to machine complex shapes and features on workpieces, such as cavities, slots, and grooves.

An end mill consists of two parts: the shank and the slot. The tool holder is held in place by the collet, and the groove does the cutting work. The number of flutes varies according to the application, it has 1 cutting edge, 2 cutting edges, 3 cutting edges and 4 cutting edges, some finishing requires 6 flutes, where two and four flute end mill applications The most extensive.

End mills are made from different materials for different applications, including high-speed steel, solid carbide, and diamond. Sometimes, coatings and treatments are used to improve its performance and durability. Coating materials include TiN, TiCN, ZrN, etc.

There are many types of end mills including up milling, climb milling, compression mills, ball nose mills, V-mills, roughing cutters, fishtail mills, etc.

What are router bits?

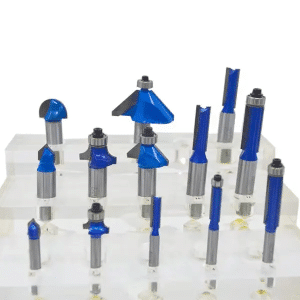

Router bits are commonly used in woodworking projects for cutting, joining, carving, and profiling. Similar to end mills, milling cutters consist of a shank and a groove. There are many types of router bits, including straight bits, helical bits, round bits, chamfer bits, tongue and groove bits, Roman reverse bits, etc.

Differences: End Mills vs. Router Bits

Application: Router bits are primarily used for cutting and shaping softer materials such as wood, plastics, etc., while end mills are designed for cutting, plunge milling, and milling harder materials such as metals.

Geometry: Router bit comes in various shapes such as spiral, straight, round, chamfered, etc., while end mills usually have flat or spherical cutting tips.

Shank Size: Typically, end mills come with larger shank diameters than router bits to perform heavy-duty tasks and provide stronger clamping force.

Cutting speed: End mills typically run at a higher speed to increase efficiency, while router bits spin at a relatively low speed to avoid burning the workpiece.

In short, the above are the main points of their differences. Hopefully this document will give you a better understanding of both products.

DH has extensive experience supplying industrial quality milling cutters to furniture factories, woodworking tool distributors and other companies around the world. If you are looking for a reliable milling cutter supplier for your business, please feel free to contact us.